VITA ENAMIC – CAD/CAM hybrid ceramics for minimally invasive restorations

Computer-supported chairside treatments are very important in my dental practice. The hybrid ceramic VITA ENAMIC (VITA Zahnfabrik, Bad Säckingen, Germany) has definitely been my favorite material for this purpose since its market introduction over three years ago. The material concept convinced me immediately – a dominant ceramic network enhanced by a polymer network. At the same time, this gives the hybrid ceramic a high elasticity and load capacity. The following case report describes an inlay restoration with this material.

Initial situation

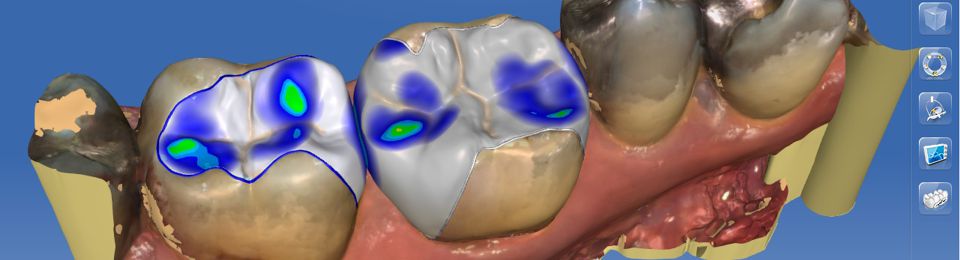

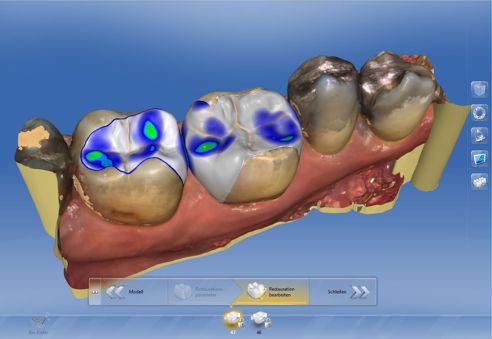

The patient had insufficient amalgam fillings with cracks and secondary caries in region 36 and 37 (Fig. 1). After the consultation, the patient decided on a ceramic restoration using the CEREC process (Sirona Dental, Wals, Austria). VITA ENAMIC was the material of choice. It offers the required durability and reliability for the masticatory force-bearing lateral tooth area and can be ground very thin thanks to its elasticity. This means it can be prepared in a manner that is more substance-protective than with traditional CAD/CAM ceramics and as much of the healthy tooth structure as possible can be preserved (Fig. 2).

The treatment procedure

The new restorations were constructed using the CEREC 3D Software, Version 4.4 (Fig. 3 and 4). The inlays were manufactured using the Sirona inLab MC XL grinder (Sirona Dental) from VITA ENAMIC HT blanks (HT=High Translucent) in the shade 1M2. For shade determination, we decided on the combination of the VITA Linearguide 3D-MASTER shade scale with the digital shade measuring device VITA Easyshade V.

After removing the grinding pin, the restorations were tried in to check the fit and the approximal and occlusal contacts. For the finishing work, only very fine diamond-coated grinding tools and polishers are recommended. No hard metal instruments can be used. The restorations were fixed directly under a rubber dam with a multi-bottle adhesive and heated filling composite (Fig. 5). The manufacturer offers its own polishing set developed by VITA ENAMIC (VITA ENAMIC Polishing Set, VITA Zahnfabrik) for pre-polishing and high-gloss polishing.

Result

What do patients want from dental treatment? The restoration should be done rapidly while protecting the tooth substance, and it must look natural. And for many patients, the cost should be reasonable. Reconstructions using the hybrid ceramic VITA ENAMIC are the ideal solution in this case. In combination with the CAD/CAM process, this is not only a medically sensible path, but also an economic one. Because dentists and patients save time and costs, and the natural tooth substance is retained.

For minimally invasive hybrid ceramic restorations, in my experience, wall thicknesses of <1 mm occlusal are possible, and restoration margins can be manually ground to almost 0 mm. The manufacturer has approved the material for crown restorations with a minimum wall thickness of 1.0 mm occlusal and 0.8 mm approximal, making VITA ENAMIC the first minimally invasive CAD/CAM hybrid ceramic material in the world. It can also be worked using CAD/CAM technology in a simpler and more rapid manner than many traditional ceramics. The total time spent for the treatment described here took less than two hours. And the restoration integrated very well with the surrounding natural tooth substance (Fig. 6). The patient was very satisfied with the result.