A new definition of load capacity: why hybrid ceramics simply offer more

Load capacity or fracture resistance is one of the key criteria in the clinical success of restorative dental materials for CAD/CAM applications. Yet there are a variety of contributory factors that must be taken into consideration when evaluating the stability of a material. However, the good news for dental practices and laboratories that use CAD/CAM technology: the results for the new hybrid ceramic have been extremely promising in a wide variety of tests.

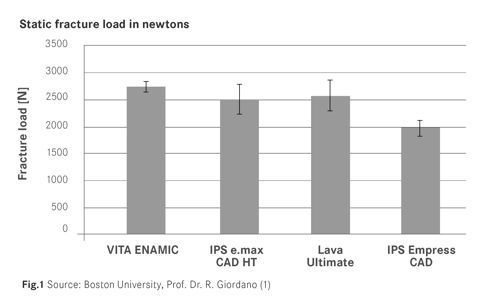

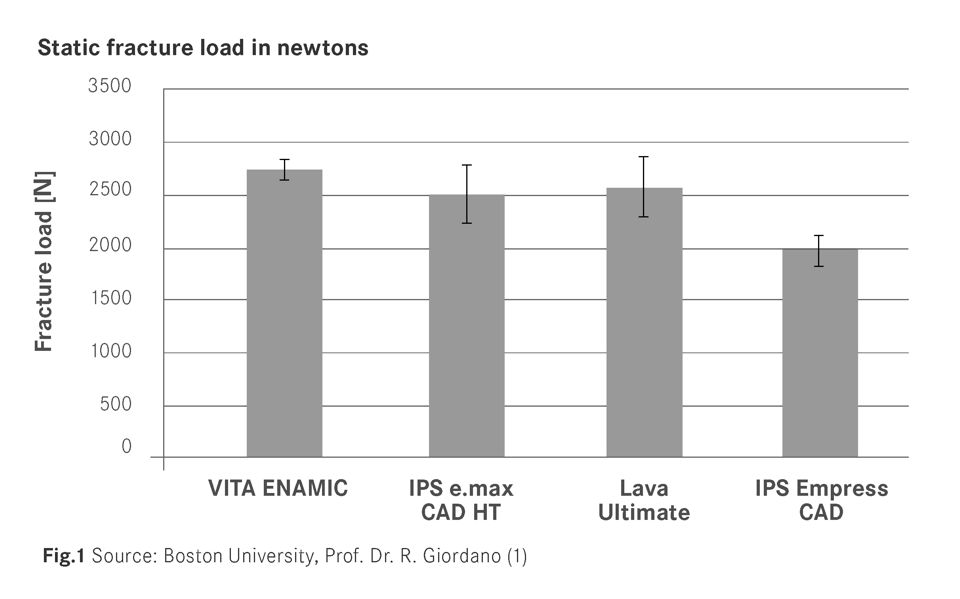

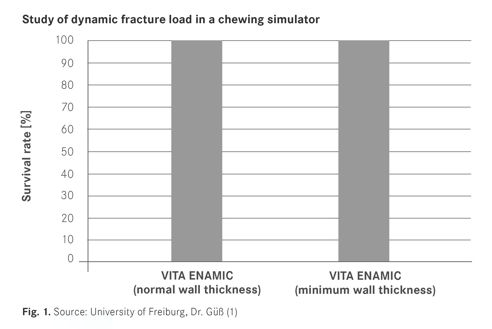

In dentistry, the load capacity of a material often refers to in-vitro fracture testing (what is generally known as flexural strength) that is measured in megapascals (MPa)."However, as studies on the new hybrid ceramic demonstrate, high flexural strength does not always equal high fracture resistance. Thanks to its resilience and elasticity, VITA ENAMIC offers exceptional resistance, even though its flexural strength is lower than that of other CAD/CAM materials". These are the thoughts of Dr. Michael Sadoun of the University of Paris.

Intelligently combining strength and elasticity

In this hybrid ceramic, strength and elasticity are intelligently combined to provide dental practices and laboratories that use CAD/CAM technology with an exceptionally fracture-resistant material. The seamless ceramic network structure and organic polymer network structure are used to replicate the structure of natural dentition. According to Prof. Michael Swain of the University of Otago: "It is this combination of modulus of elasticity and high resilience, which is comparable to that of natural dentition, that makes the difference compared with conventional ceramic and composite materials. This means that most ceramic materials offer a higher modulus of elasticity than VITA ENAMIC, i.e. they provide superior stiffness (by a factor of 2 in fact), and typically fail with an elongation at break of 0.1 %. However, due to the polymer network that is integrated throughout the material, VITA ENAMIC facilitates levels of stability that are four times higher, despite a lower modulus of elasticity. As a result, VITA ENAMIC can withstand levels of elongation at break that are 200 - 400 % greater than most other ceramics before fracturing. This behaviour is particularly significant in the oral cavity where the dentition in the dental arch is primarily responsible for limiting the elongation at break that a tooth can withstand."

Load tests passed successfully

During determination of the static fracture load, the VITA ENAMIC hybrid ceramic proved its exceptional load capacity with a fracture load of approx. 2766 newtons – the highest load value of any material evaluated during this test. The new material also achieved above-average results in testing with the chewing simulator: the hybrid ceramic demonstrated a 100% survival rate both with walls of normal thickness and with those of minimal thickness.

Bibliography

1) Studies published in "Technical and scientific documentation" 10.13

VITA Zahnfabrik H. Rauter GmbH & Co. KG Research and Development Division | Inorganic Chemistry | Spitalgasse 3 | 79713 Bad Säckingen

Dr. Enno Bojemüller, Division Manager – Inorganic Chemistry (R&D), Bad Säckingen

Dipl.-Ing. Andrea Coldea, Material Development, R&D Inorganic Chemistry, Bad Säckingen

Dr. Norbert Thiel, Division Director R&D – Inorganic Chemistry, Bad Säckingen