A study of the abrasion behavior of full crowns fabricated using CAD/CAM processing

With the advent of fabrication supported by CAD/CAM technology, dental practices and laboratories can now choose from a variety of materials. For practitioners, the scientific validation of material solutions is an important prerequisite in selecting the most appropriate material in each specific case. The University of Witten/Herdecke has investigated the abrasion behavior of several CAD/CAM materials as part of an in vitro study. In this interview, Prof. Andree Piwowarczyk (Chair of the Institute of Dental Prosthetics and Dental Technology) presents the study as well as findings that are of practical relevance.

DV: Prof. Piwowarczyk, what did the study investigate and what was the objective?

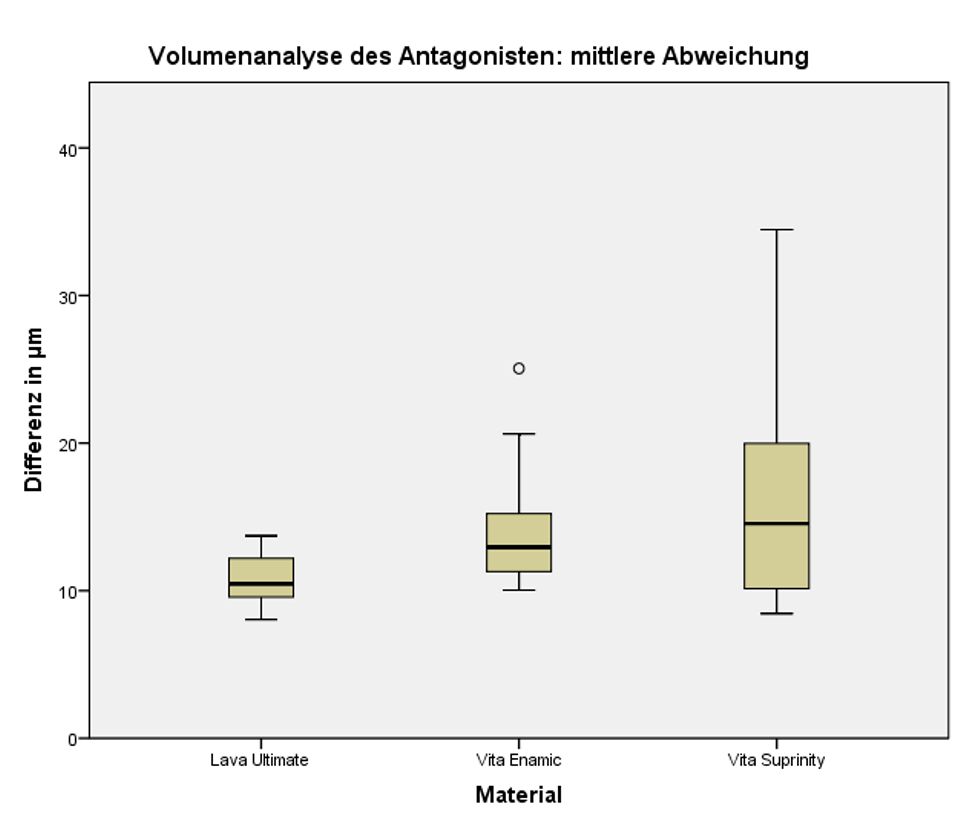

Prof. Piwowarczyk: The in vitro study investigated the abrasion behavior of different CAD/CAM-fabricated, tooth-colored restoration materials in connection with human dental hard tissue. Based on fabrication supported by CAD/CAM technology, crowns were created using the following materials while taking the antagonist dentition (non-carious human molar) into consideration: Resin Nano Ceramic (Lava Ultimate, 3M ESPE), hybrid ceramic (VITA ENAMIC, VITA Zahnfabrik) and zirconia-reinforced lithium silicate ceramic (VITA SUPRINITY, VITA Zahnfabrik). The objective of the study was to be able to indicate which material is the most gentle on dental hard tissue. A further aim was to clarify which of the three materials offers the greatest abrasion resistance. However, the crucial element was to identify a material that is both exceptionally antagonist-friendly as well as offering stable occlusal relationships in the long term.

DV: How abrasion-resistant is the hybrid ceramic VITA ENAMIC in comparison to other restoration materials?

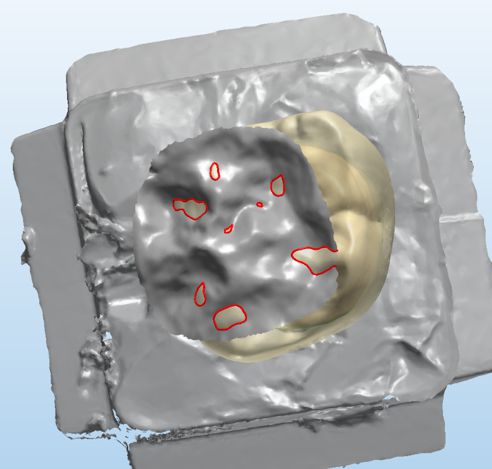

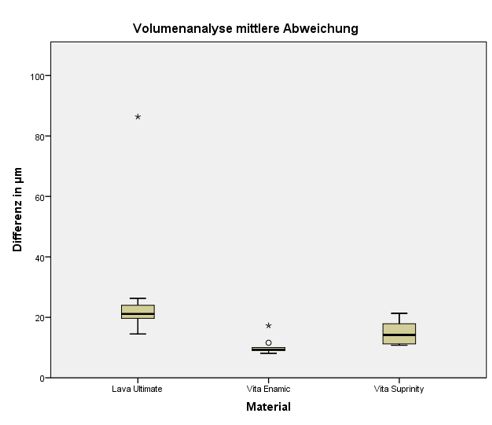

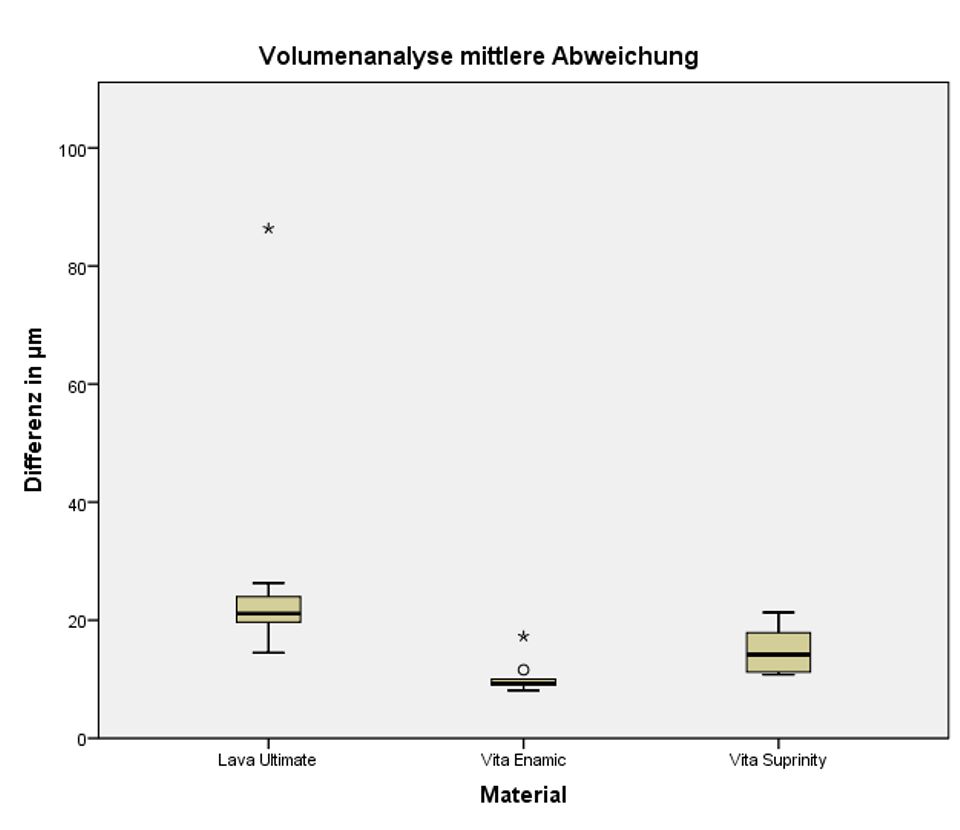

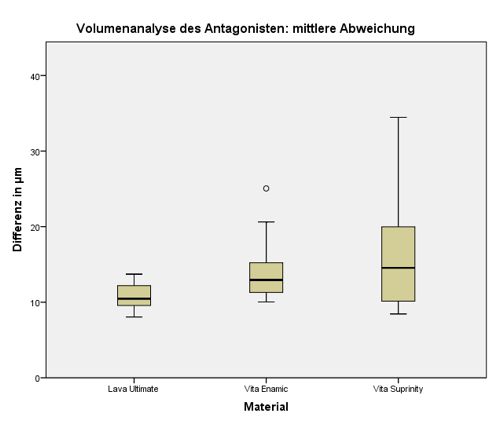

Prof. Piwowarczyk: VITA ENAMIC is the most abrasion-resistant material in our study design. With regard to evaluation of the entire occlusal surface of the crown, the hybrid ceramic achieved median values in terms of average abrasion of 9.3 µm (interquartile range 8.9-10.4 µm). This was followed by VITA SUPRINITY with abrasion values of 14.1 µm (11.1-18.4 µm). At 21.1µm (18.6-24.5 µm), Lava Ultimate showed the highest median value in terms of average abrasion. In the case of human antagonists, we observed the following: in combination with Lava Ultimate, the median value of average abrasion was 10.4 µm (interquartile range 9.5-12.4 µm). In combination with VITA ENAMIC and VITA SUPRINITY, the antagonists achieved median values of 12.9 µm (11.2-16.5 µm) and of 14.5 µm (9.7-20.8 µm). Overall, VITA ENAMIC offers significant abrasion resistance and is highly antagonist friendly.

DV: What is the significance of these results for the clinical use of VITA ENAMIC?

Prof. Piwowarczyk: In the case of VITA ENAMIC, the amount of substance loss for the crowns was comparable to that of the antagonists. This means that following in vitro occlusal simulation approximately equivalent to that of five years, the amount of substance loss in the crown and antagonist region is lower as well as more uniform. It can be assumed that in clinical use, VITA ENAMIC provides for stable occlusal relationships in the long term as well as protecting the natural dental hard tissue.

DV: Looking ahead, where do you see the new hybrid ceramic VITA ENAMIC in a few years' time?

Prof. Piwowarczyk: My assumption is that the hybrid ceramic VITA ENAMIC will continue to establish itself. This will require a sustained information campaign. As is the case with any new material, practice and laboratory users require detailed explanations and support in this respect with regard to the technical and medical procedures required from a dental perspective. Practical training in particular, which includes both the technical as well as the medical aspects from a dental perspective, is an important instrument in this regard. Based on the findings that we have determined, the VITA ENAMIC material can be considered a "tooth-friendly restoration".

DV: Thank you for talking to us, Prof. Piwowarczyk!