VITA ENAMIC: new developments from science and research

Professor Russell Giordano (Boston University, Henry M. Goldman School of Dental Medicine, USA) already registered the first patent in 1996 for the VITA ENAMIC hybrid ceramic. His research work was an important milestone in the continued further development of the material up until its introduction to the market in 2013. Over the last few months, he has also carried out a variety of performance tests with the new CAD/CAM material, which he reports on in the following interview.

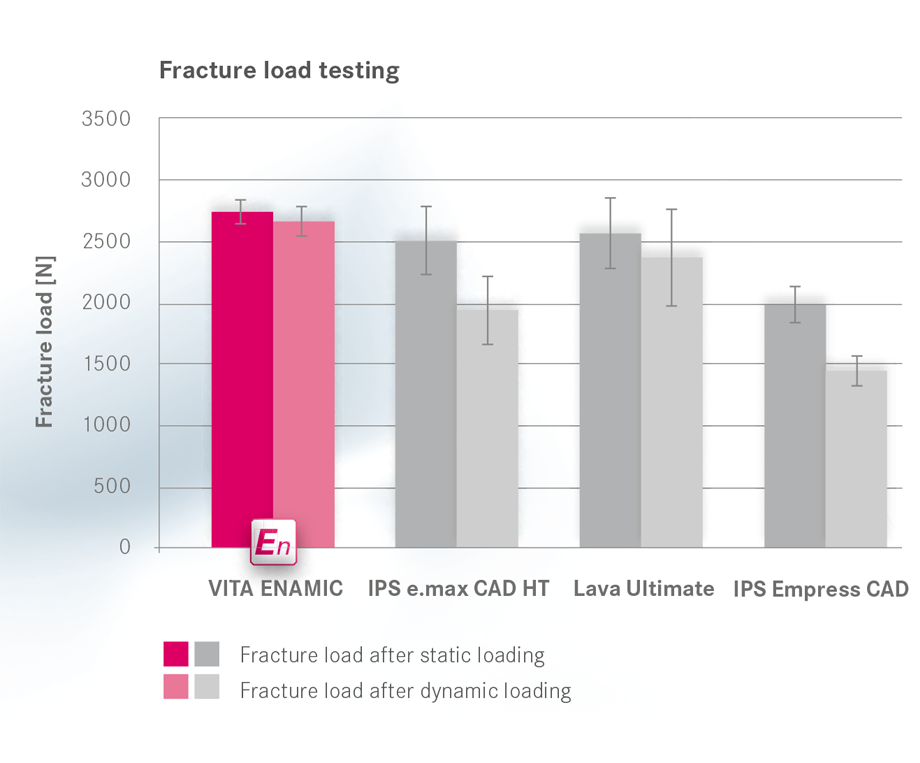

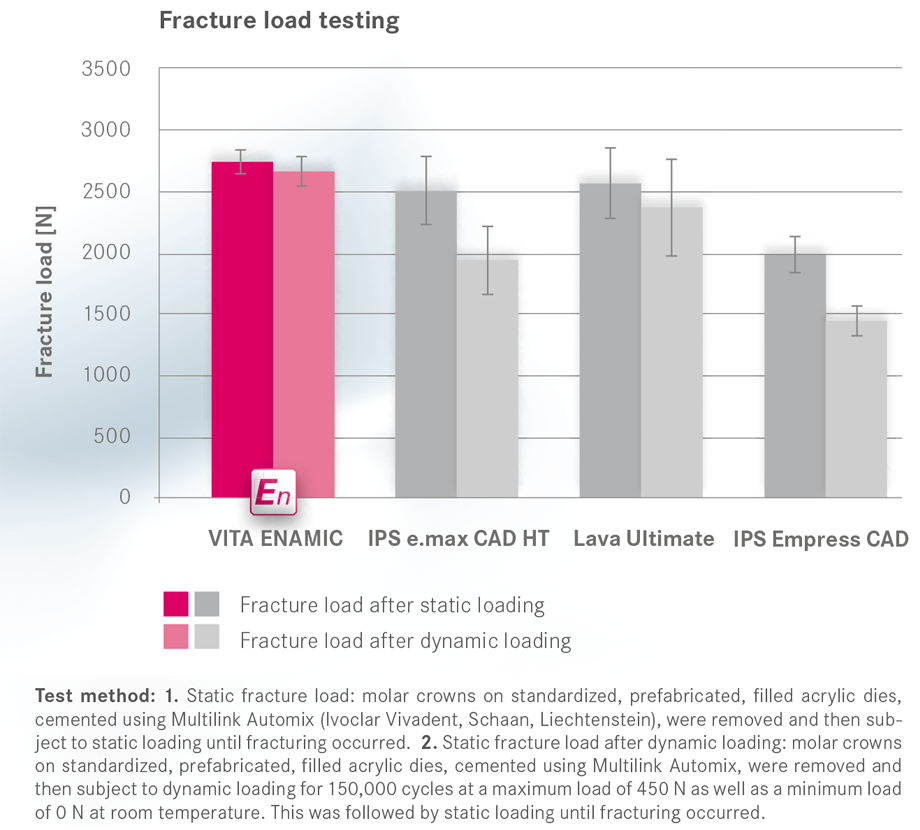

DV: Prof. Giordano, during the course of fracture load testing you compared the VITA ENAMIC hybrid ceramic with other CAD/CAM materials – what was the result?

Professor Russell Giordano: In a comparison of crown restorations (with an occlusal wall thickness of 1.5 mm and marginal wall thickness of 1.0 mm) fabricated using VITA ENAMIC and IPS e.max CAD (Ivoclar Vivadent, Schaan, Liechtenstein), a higher mean value was determined for the hybrid ceramic in static fracture tests, although the fracture load values for both materials were within a similar range. When the same fracture load test was conducted following dynamic loading of the materials, VITA ENAMIC achieved a fracture load value that was significantly higher than that of IPS e.max CAD.

DV: How should this be interpreted?

Professor Russell Giordano: In the dual network structure of VITA ENAMIC, the ceramic network forms a stable "backbone", while the polymer network stops cracking. Both networks are not only integrated with one another, they also each form a separate, intact structure. In composites on the other hand, such as Lava Ultimate (3M ESPE, Seefeld, Germany), for example, there are many individual ceramic particles that are surrounded by a polymer matrix. VITA ENAMIC is also different to conventional ceramics: these may offer high strength, however, they are also comparatively brittle and therefore cannot deform so easily without fracturing as a result.

DV: Is a lesser tendency towards material fatigue to be expected in VITA ENAMIC than in conventional ceramics?

Professor Russell Giordano: Natural teeth often show numerous microcracks or enamel cracks, and yet the patient will have them for their entire lives. For this reason it is also important in a restorative material that any microcracks that do occur do not lead to failure of the restoration. Thanks to its polymer network, VITA ENAMIC can absorb compressive load and stop any cracks that may occur.

DV: What did you and your team at Boston University find particularly convincing during clinical application of VITA ENAMIC?

Professor Russell Giordano: VITA ENAMIC offers shade stability and can be easily and quickly machined using the Sirona MC XL unit (Sirona Dental GmbH, Wals, Austria), while also facilitating a longer service life for milling tools. A wall thickness of 0.3 mm can be achieved with exact edges, and without the "chipping issue" that is otherwise often typical of conventional ceramics. VITA ENAMIC veneers can even be reduced to as far as 0.2 mm. This allows a significant gap in the range of CAD/CAM materials to be filled. Even our dean Prof. Jeffrey W. Hutter has VITA ENAMIC restorations!