New prospects and opportunities – digital dentistry 2.0

For Dr. Gerhard Werling (Bellheim, Germany) and Dr. Bernhild-Elke Stamnitz (Langen, Germany), the new hybrid ceramic has, up until now, not just clearly proven its worth, but also extended the range of possibilities in computer-aided fabrication of restorations. In the following interview, these two practice users report on how this revolutionary material is creating new opportunities for digital dentistry 2.0.

Dr. Gerhard Werling, Bellheim, Germany

DV: Dr. Werling, what type of restorations are you now carrying out using the hybrid ceramic that previously, were rarely possible using conventional, tooth-colored CAD/CAM ceramics?

Dr. Gerhard Werling: VITA ENAMIC is ideally suited to delicate, minimal-invasive constructions, and always in cases where a highly precise marginal fit is required. In the treatment of severely abraded dentition or in the case of those who grind their teeth, I consider the hybrid ceramic to be a good alternative material to conventional ceramic, even if this has not yet been officially approved by the manufacturer due to the lack of sufficient clinical data.

DV: In your presentations, the topics you discuss also include what is known as a "digital mock-up". What do you mean by that and how do you actually carry this out in your practice?

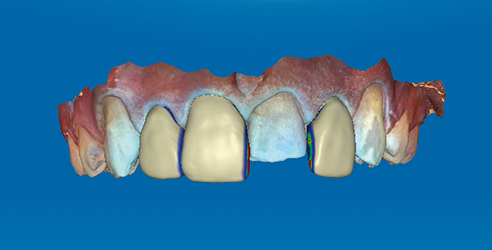

Dr. Gerhard Werling: For test purposes, we fabricate the planned restoration from VITA ENAMIC using computer technology. If we are performing an additive optimization such as crown lengthening, this mock up can also be used as a permanent non-prep restoration if the patient is happy with it.

DV: Why do you consider the new hybrid ceramic in particular to be especially suited to the "innovative" CAD/CAM-based approaches to restoration that you have mentioned?

Dr. Gerhard Werling: Thanks to the high level of edge stability, the edges of the restoration can be polished so thinly that the transition to the natural tooth substance is almost "invisible", particularly when using VITA ENAMIC polishing instruments.

Dr. Bernhild-Elke Stamnitz, Langen, Germany

DV: Dr. Stamnitz, in a case documentation that you have published you demonstrate the fabrication of what are known as tabletops, i.e. occlusal veneers for the reconstruction of occlusal surfaces. What led you to use VITA ENAMIC for this purpose?

Dr. Bernhild-Elke Stamnitz: The hybrid ceramic provides a perfect fit, optimum shaping of the edges, superb durability as well as elasticity similar to that of dentin. In addition, many of my patients find that a VITA ENAMIC restoration feels like a natural tooth rather than a foreign object, unlike other materials such as monolithic zirconia or lithium disilicate.

DV: What other "innovative" approaches to restoration have you realized using VITA ENAMIC that you have not previously attempted while using the CEREC system, and why?

Dr. Bernhild-Elke Stamnitz: Teeth that have been severely damaged up to gingival level or further can be stabilized using VITA ENAMIC post abutments. In my opinion, the hybrid ceramic is an excellent choice in this case due to its elasticity that is similar to dentin. However, as long-term clinical experience is not yet available, this procedure is still experimental.

DV: Dr. Stamnitz, practice users are impressed by the processing characteristics that VITA ENAMIC offers when using CAM technology, for example such as the short milling times. How has this changed your workflow?

Dr. Bernhild-Elke Stamnitz: The milling process using CEREC MC XL takes longer when using conventional dental ceramics such as lithium disilicate. Moreover, ceramics such as lithium disilicate also require crystallization firing. VITA ENAMIC restorations, on the other hand, can simply be polished after milling in most cases, and seated immediately.