Materials and procedures in tooth production: MRP composite versus PMMA

Today, the denture teeth available on the market are mostly manufactured from polymethyl methacrylate (PMMA). In contrast to the classic “PMMA denture teeth,” VITA manufactures the majority of its dental products from MRP composite (Microfiller Reinforced Polymer Matrix). This is a highly crosslinked polymer matrix with homogeneously distributed, inorganic polymerized microfillers. In the following article, Dr. Stefan Aechtner (Project Manager for Material Development at VITA R&D, Bad Säckingen, Germany) explains the central differences in materials and procedures in industrial tooth manufacturing.

Characteristics of dental materials

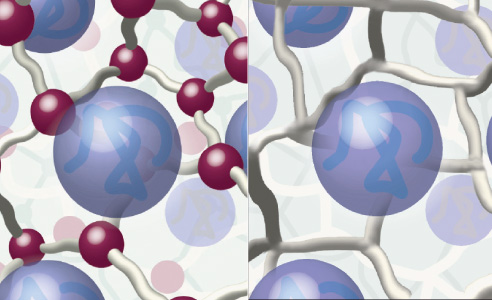

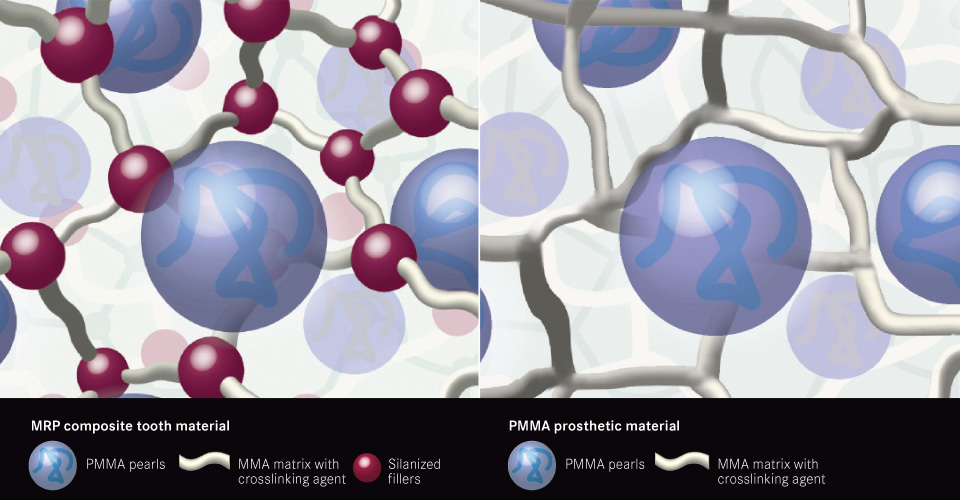

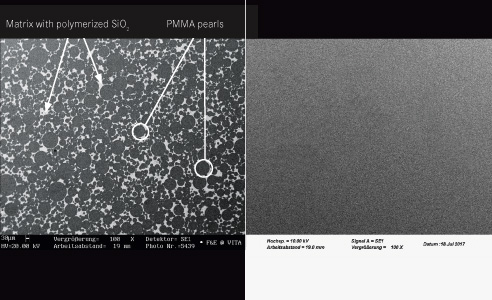

During manufacture of the VITA MRP composite, the silicon dioxide fillers (SiO2/pyrogenic silica) are surface-modified or silanized at VITA in a special process to ensure excellent bonding to the PMMA matrix. The SiO2 filler acts as an additional crosslinking agent during polymerization. The strengthening of the polymer matrix with microfillers ensures an excellent wear resistance for MRP composite products. PMMA materials (polymethyl methacrylate), on the other hand, are a synthetic acrylic without inorganic fillers. PMMA denture teeth exhibit comparably lower durability in tests than dental products made of composite.

Procedures for fabricating teeth

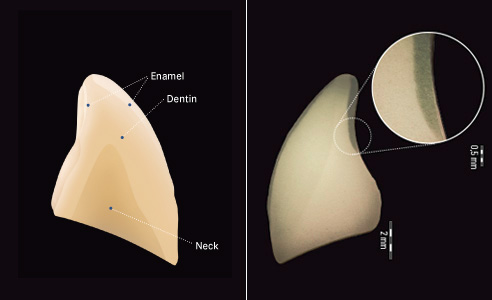

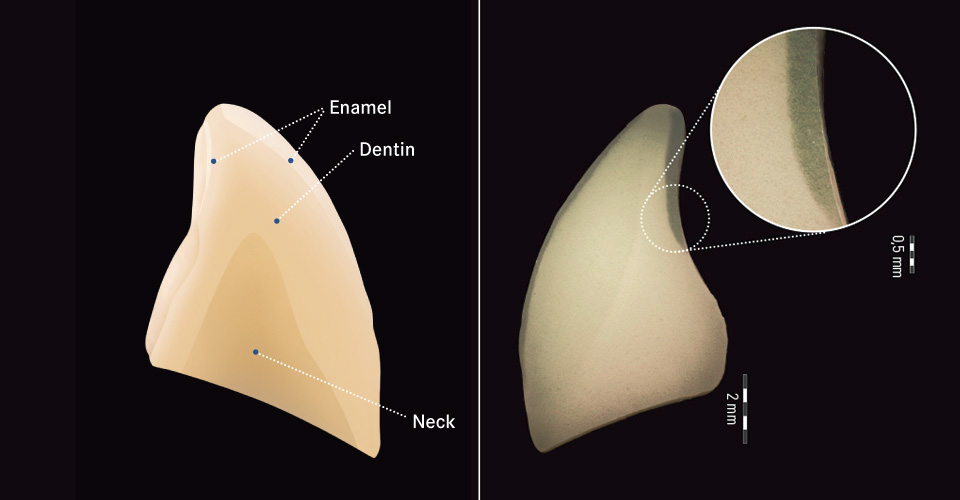

In general, today’s modern denture teeth are built up layer-by-layer from different types of material. However, there are fundamental differences in tooth manufacture, depending on the material base. With MRP composite, the different materials are layered, one after the other, into the tooth molds until the mold is completely filled. After this, the materials are compacted and cured under pressure and heat. The polymerization of the entire denture tooth is done in a single step. The materials penetrate each other completely at their boundary layers and a gap-free and pore-free bond is achieved. In the case of PMMA prefabricated teeth, the materials are successively layered or pressed into the tooth molds. Here, each individual layer is fixed in position by heating under pressure to ensure that the mold can be opened for introducing the next layer. Finally, the final polymerization follows, which fully polymerizes the material.

100 % German Dental Engineering

VITA is committed to the motto of "100 % German Dental Engineering," and has been combining German engineering skill with practical dental knowledge and technology since 1924. VITA denture teeth are made from MRP composite and manufactured according to the highest production and quality standards, exclusively in southern Germany, at the company's headquarters. Here, specially trained, skilled personnel produce the denture teeth using both automated processes and customized manual production.

Report 07/17