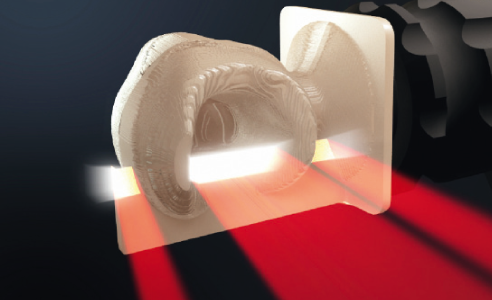

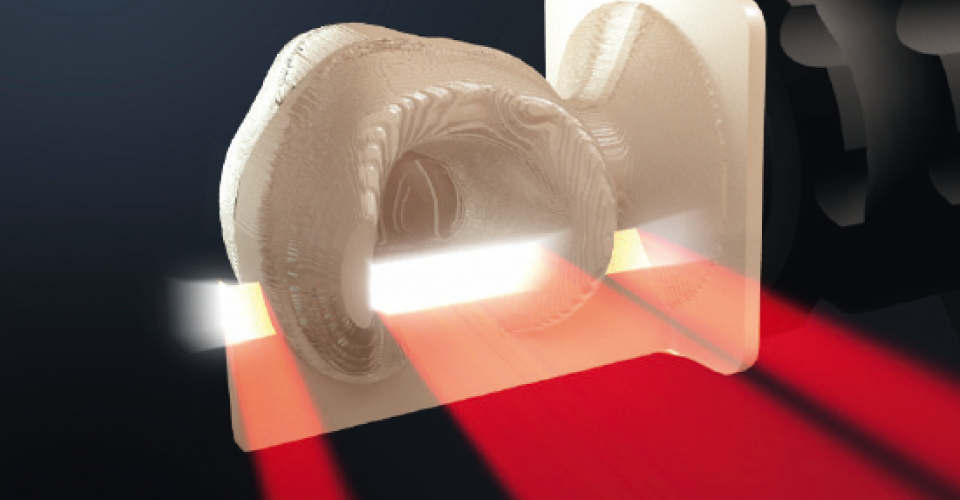

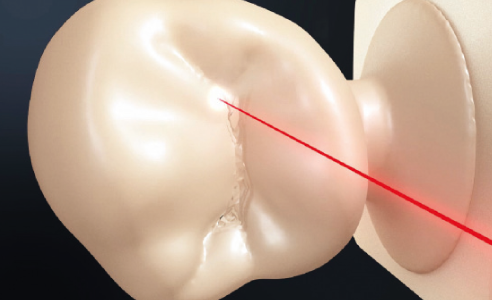

"Laser milling" – an innovative manufacturing technology for restorations

The Laser Mill system (Dental Wings, Montreal, Canada) uses millions of short, high-intensity laser pulses to remove many thin material layers from a blank and are similar to the design in the manufacture of dental prostheses. From mid-2017, the fully open digital workflow will be available from the intra-oral scanner in selected markets via the appropriate CAD software to the innovative Laser Mill unit. The first tested material for this new processing technology is the hybrid ceramic VITA ENAMIC (VITA Zahnfabrik, Bad Säckingen, Germany). In the following interview, Pierre-Olivier Roy (Vice President of Dental Wings, Montreal, Canada) explains the specifics of the technology and the advantages it holds for practices and laboratories.

DV: What are the significant differences between milling and laser technologies?

Pierre-Olivier Roy: The most significant difference is in that no tools are necessary for fabrication. The laser removes the material using a very short laser pulse. That is the reason why there is no wear. The detailed restoration work takes place step by step with the substance removal.

DV: What advantages does Laser Mill offer for dental laboratories and practices?

Pierre-Olivier Roy: Very delicate restoration work can be done with the extremely fine laser beam. Manufacturing with this system is more straightforward, since no tools, no compressed air, or water are needed. Installation is easy. Complex geometries can be machined without issue.

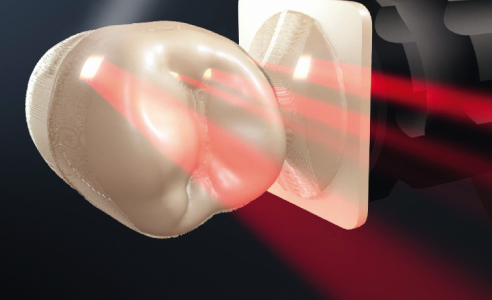

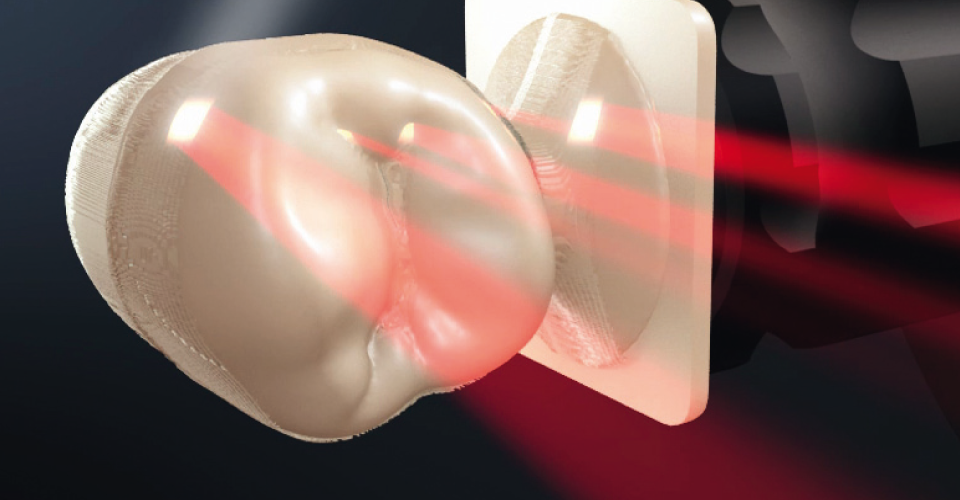

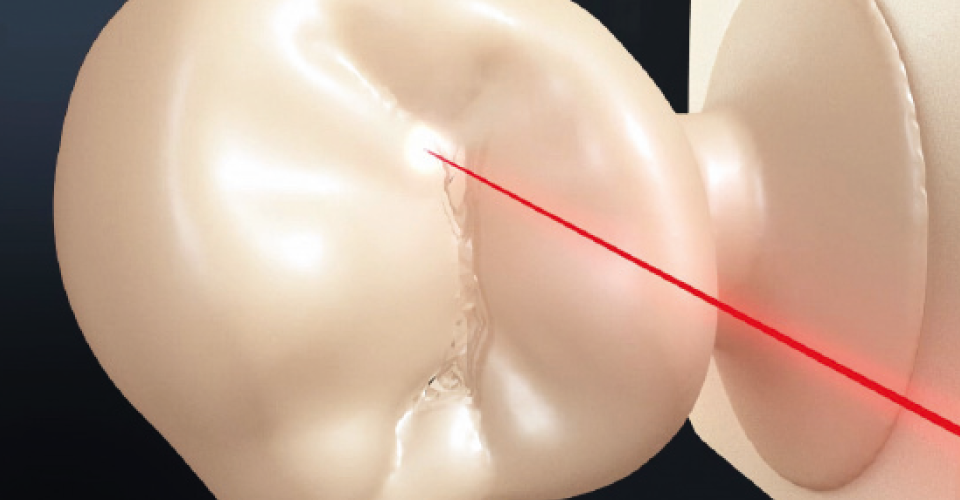

DV: Why is the hybrid ceramic, VITA ENAMIC, particularly suitable for the Lasermill?

Pierre-Olivier Roy: The robust dual network structure of the hybrid ceramic makes fast, precise and predictable material removal possible. VITA ENAMIC is the first CAD/CAM material approved for clinical use because of its good material properties for laser milling. Additional ceramic chairside materials, such as VITABLOCS Mark II, will follow.