An intelligent treatment concept for the implant-supported individual tooth crown

For good healing success and predictable gingiva management during implantation, the soft tissue needs as much rest as possible. Gingiva formers, which also act as a scan body, provide the opportunity to perform a scan without disturbing the healing process. In this case, Dr. Oliver Schubert, M.Sc. (Munich, Germany), shows how he implements such a process. He also explains why he uses a

hybrid ceramic blank (VITA ENAMIC IS, VITA Zahnfabrik, Bad Säckingen, Germany) with an integrated interface to a titanium base. He shows how the abutment crown made of hybrid ceramic directly after the removal of the gingiva former supports the final shaping of the emergence profile.

1. The patient case

A 55-year-old female patient presented with complaints regarding tooth 26. After careful clinical and radiographic diagnosis, the molar proved unsustainable. After extraction, the gap was to be closed with an implant and a monolithic abutment crown made of VITA ENAMIC IS. Due to the dual network structure of the polymer-infiltrated feldspar ceramic, the material shows a comparatively high elasticity, which allows the material to absorb masticatory forces. This property could be very beneficial in the long run for restorations on rigidly anchored implants. In addition, laboratory tests show that microcracks caused by a potential point overload can be stopped, thanks to the integrated polymer structure, which minimizes fracture risk. At the patient's request, the restoration of the previously root canal-treated tooth 25 was to be done later.

2. Implantation and scan

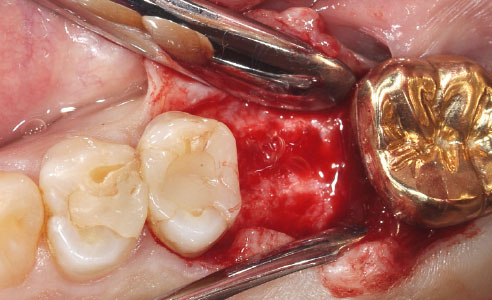

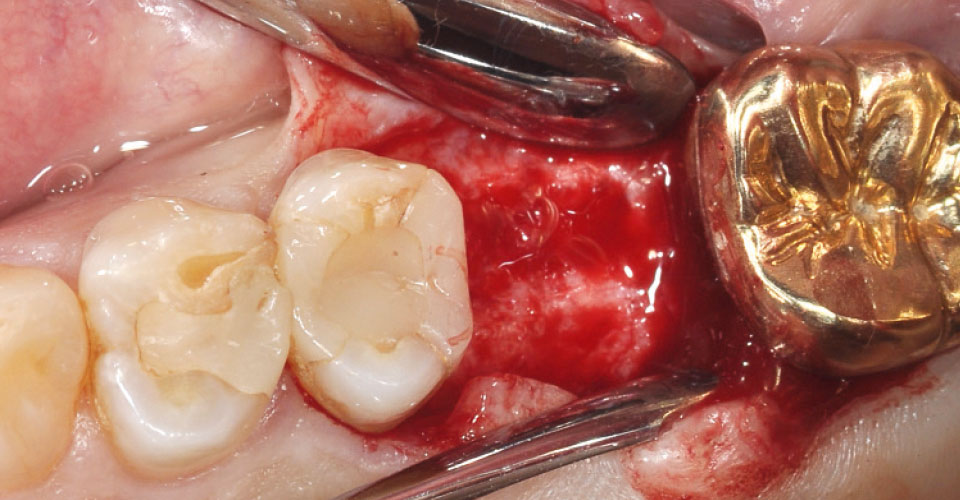

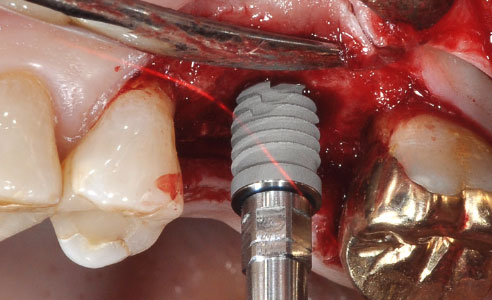

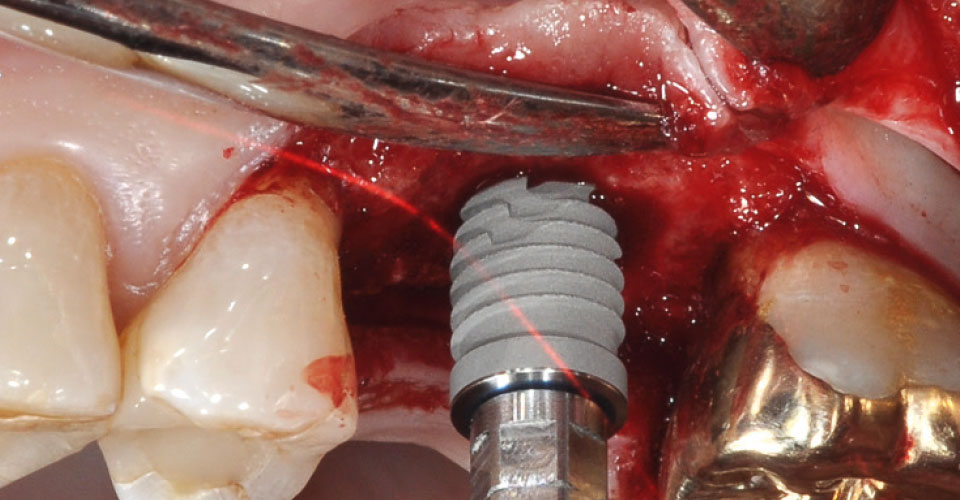

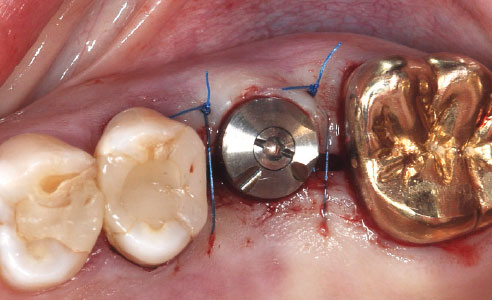

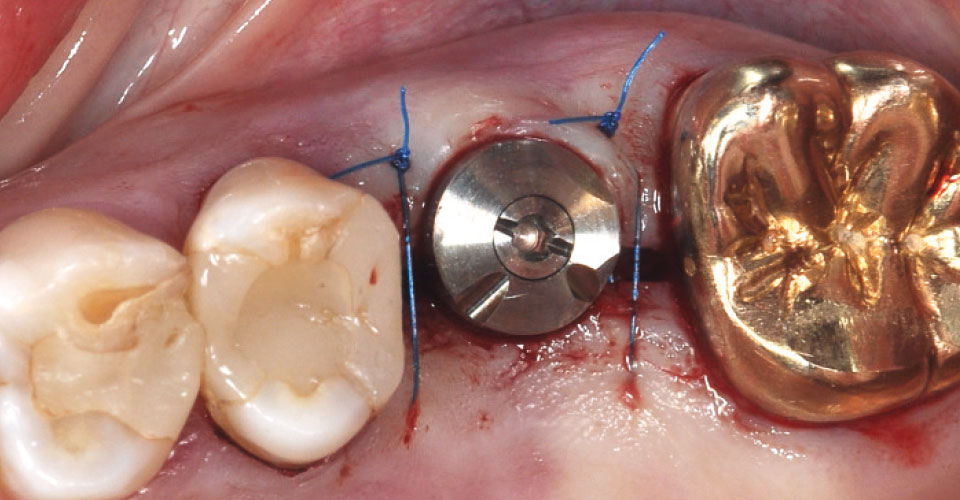

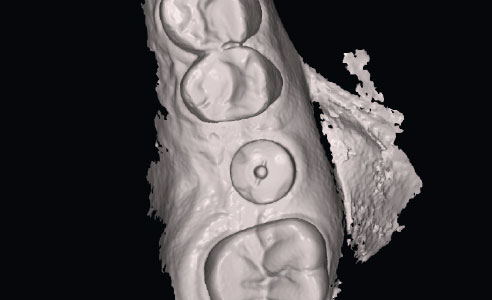

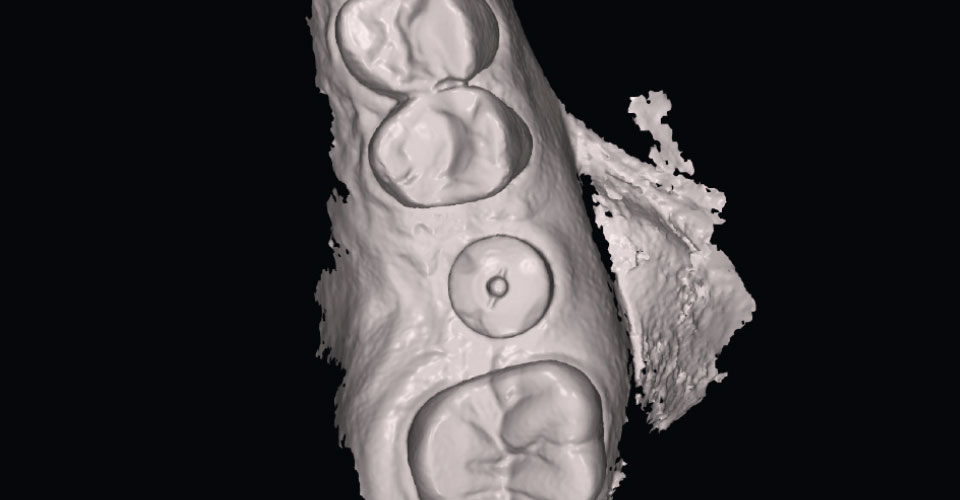

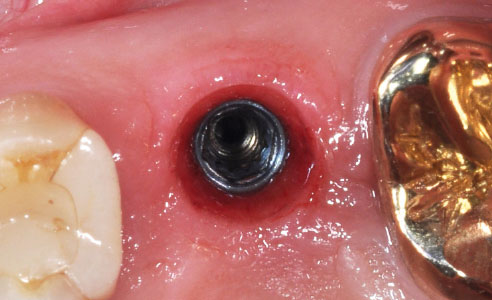

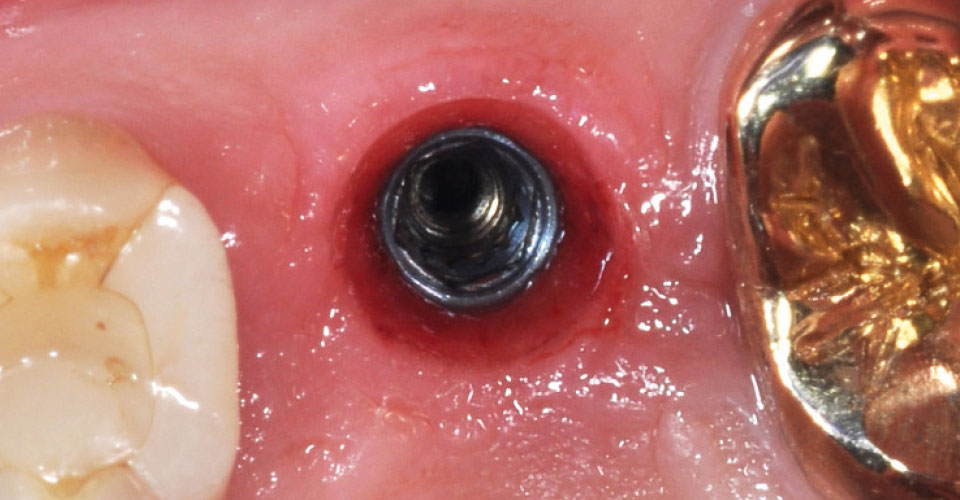

After bone-sparing extraction and sixteen weeks of healing, the gap in the edentulous space should be restored with the 3i T3 Tapered implant (Zimmer Biomet, Warsaw, USA). After the formation of a full flap, the bone bed was prepared accordingly and the implant inserted and aligned with the prosthetic, so a primary stability of 35 Ncm could be achieved. Subsequently, the two-part, scannable gingiva former BellaTek Encode (Zimmer Biomet, Warsaw, USA) was fixed on the implant and the wound area was fixed with microsurgical sutures. Eight weeks after implant insertion, the intra-oral scan of the gingiva former and the digital implant impression were performed. With its specific notches on the surface, the screwed-in and left-in gingiva former now also served as a scanbody. The upper and lower jaws were digitized using the 3M True Definition Scanner (3M, Seefeld, Germany).

3. Fabrication and integration

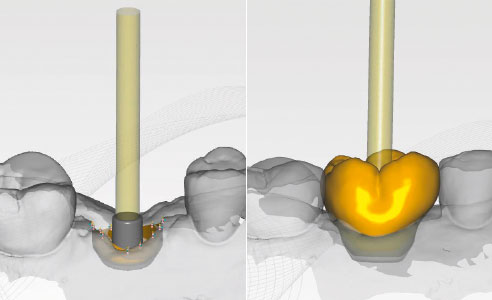

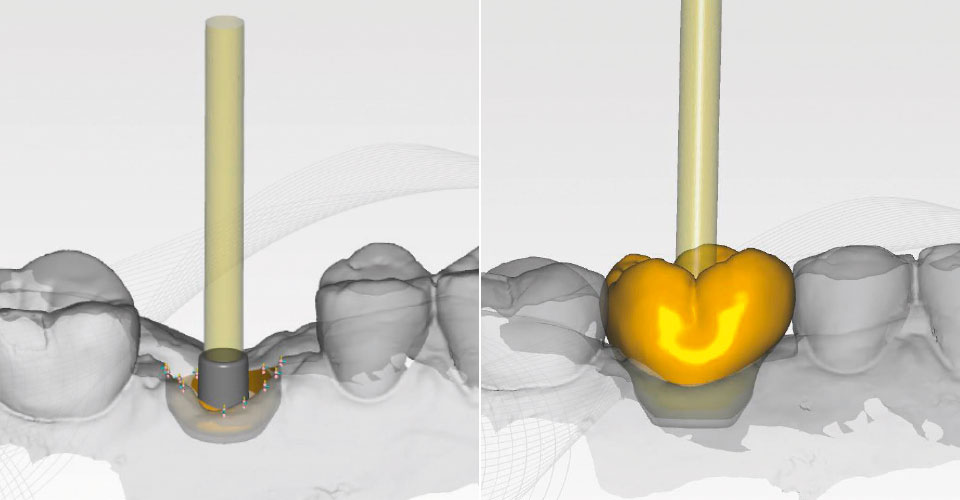

The scan data was transmitted to the Zfx Süd milling center (Munich, Germany) and downloaded there as an STL dataset. Then the scan record of the gingiva former was decrypted with the Zfx Application Manager. This automatically reduces the gingiva former, and the shape of the emergence profile is displayed in the CAD software. The abutment crown made of VITA ENAMIC IS has now been designed virtually with an idealized emergence profile. After CAM-based manufacturing, the hybrid ceramic abutment crown was bonded to the industrially produced titanium base. Immediately after unscrewing the gingiva former, the abutment crown could be screwed in to immediately support the soft tissue and provide it with its final shape. The screw channel was finally closed by Teflon tape and composite.

Report 07/18