Implant-supported restoration with VITA anterior teeth made of MRP composite

Removable, implant-supported restorations are often the solution in unfavorable anatomical conditions, as they ensure good functional stability, even in a case like this one. A central prerequisite for durable implant-supported dentures is wear-resistant denture teeth since strong chewing forces usually occur here. VITAPAN EXCELL anterior teeth (VITA Zahnfabrik, Bad Säckingen, Germany) are fabricated from particularly abrasion-resistant MRP composite material. In their report, Carolin Wehning, Dental Technician, and Dr. Babak Varzideh (Bocholt, Germany) explain how this new generation has been proven in the production of an implant-supported maxillary prosthesis.

1. Initial findings and implantation

A 56-year-old female patient presented in the dental practice because she was dissatisfied with her removable, implant-retained maxillary prosthetic from a functional and esthetic point of view. The implants were placed unfavorably with regard to the insertion direction and demonstrated mobility grade III due to the uneven stress. The patient wanted to be able to show a natural-looking, individual smile again. The new restoration was also designed to enable reliable wearing comfort during eating, as well as simple cleaning. The pronounced distal occlusion position was to be compensated for with the new dentures. After xtensive consultation, the patient decided on bridgework on four strategically placed implants. The existing implants were explanted, and four new pillars were placed in regions 14, 11, 24 and 25, in keeping with the planned prosthetic.

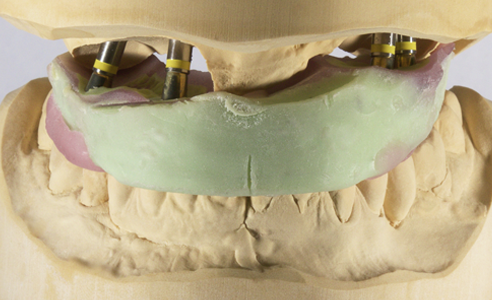

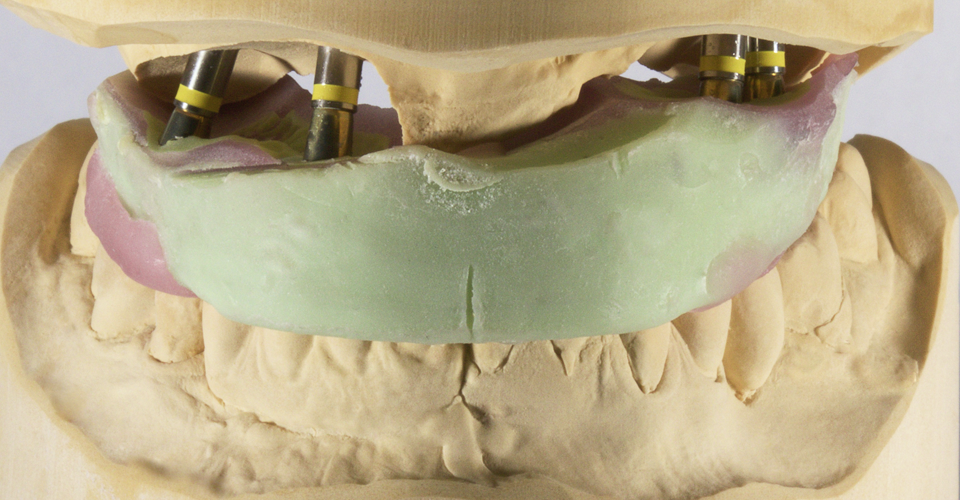

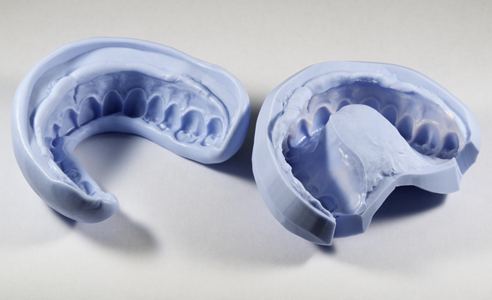

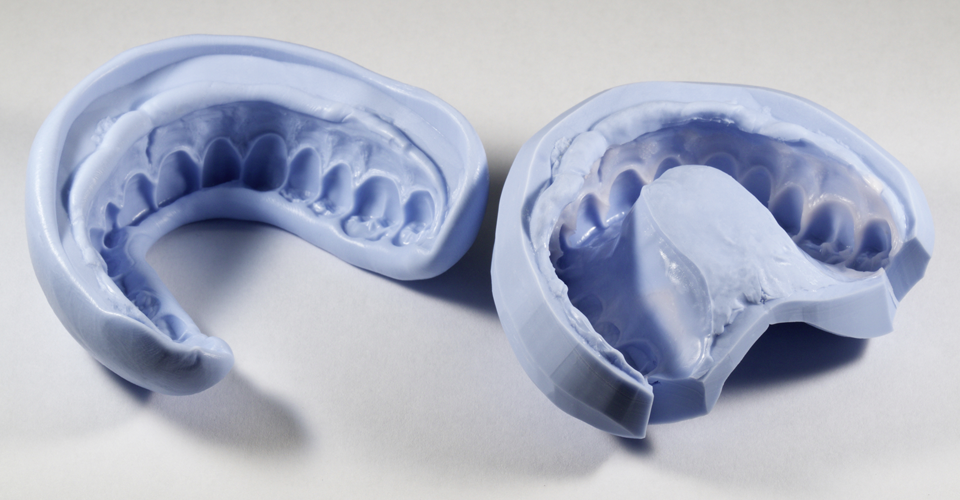

2. Impression and wax setup

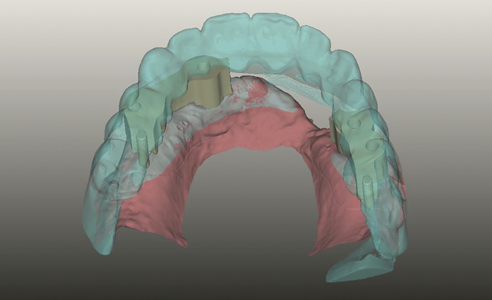

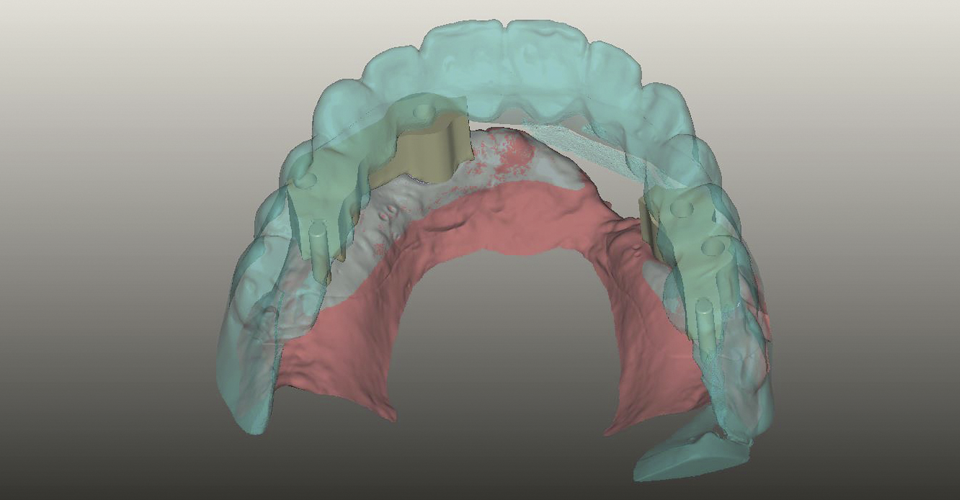

After a healing period of seven months, an open impression was taken of the situation. On the master model, a bite registration was produced from light-curing synthetic material, which was supported by the screwed-on healing caps and was lined with silicone. The occlusal situation and the midline were precisely transferred to the articulator. The dental arch of the old maxillary prosthesis was duplicated using synthetic material. The tooth shape and occlusion with the mandible were optimized per wax-up and the prosthetic base was designed from pink baseplate wax. This setup was scanned in and provided planning security during the design process of the primary (zirconia), secondary (PEEK) and tertiary frameworks (chromium-cobalt-molybdenum). The wax setup with VITAPAN EXCELL denture teeth in the esthetic zone was then done on the tertiary framework. The solidity of the anterior teeth helped balance the distal occlusion position.

3. Finalization and result

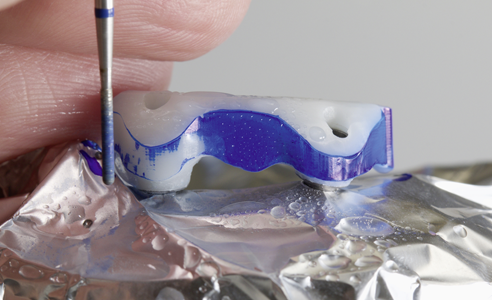

Following a successful wax try-in, the maxillary prosthesis of synthetic material was implemented. The silicone key cross-linked with VITAFOL H (silicone film) enabled a detailed reproduction of the gingival surface texture. After only minor elaboration, the vestibular portions of the denture base were sandblasted and moistened with VITA VM LC MODELLING LIQUID. For a particularly natural-looking, vibrant effect, the prosthesis was customized with VITA VM LC flow veneering composite (GINGIVA 1; old pink and GINGIVA 3; pink), as well as VITA VM LC PAINT shades. In combination with the good light dynamics of the VITAPAN EXCELL, a highly esthetic, removable restoration was created step by step. It is important that the denture teeth were ground for the framework structure, but still displayed excellent shade stability. As a result, the patient was very satisfied with the wearing comfort of the prosthesis and the esthetic appearance achieved. Carolin Wehning's summary: “The new VITAPAN EXCELL anterior tooth has a really beautiful effect in this restoration.”

Report 0/17