Hybrid ceramic versus composite: the quality of the adhesive bond in the test

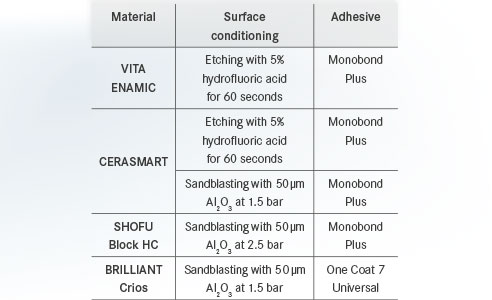

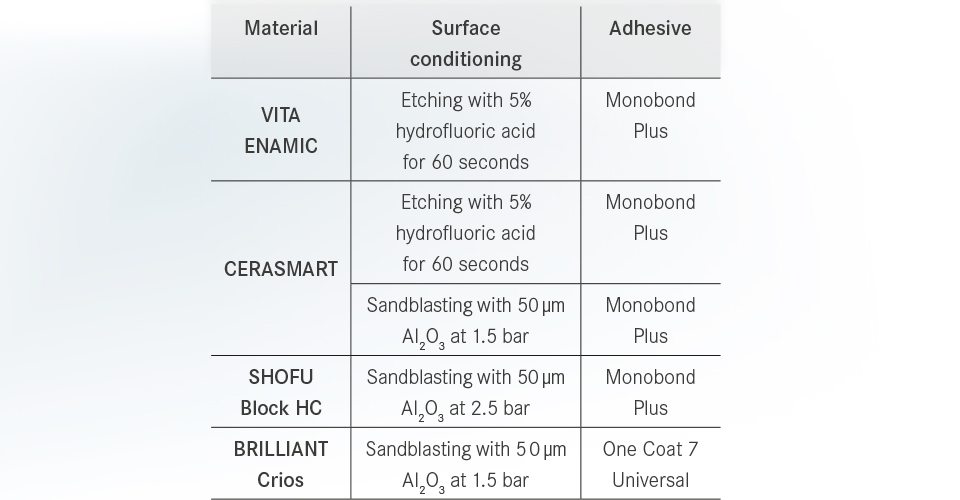

Full adhesive attachment is a key factor in the long-term durability of indirect restorations. Reliable conditioning of the material is essential here. A specific mounting protocol must be designed for each material for this purpose. The hybrid ceramic VITA ENAMIC (VITA Zahnfabrik, Bad Säckingen, Germany), for example, consists of a polymer-infiltrated glass-ceramic matrix and can therefore be etched with hydrofluoric acid. Composites, on the other hand, are sandblasted because they have a polymer matrix in which ceramic fillers are embedded. In an in vitro study, Dr. Berit Müller (Bad Säckingen, Germany) investigated the adhesive bond of an adhesive system to hybrid ceramics and composites. She reports on her discoveries in this interview.

DV: How did you go about investigating the quality of the hybrid ceramic and composite adhesive bond?

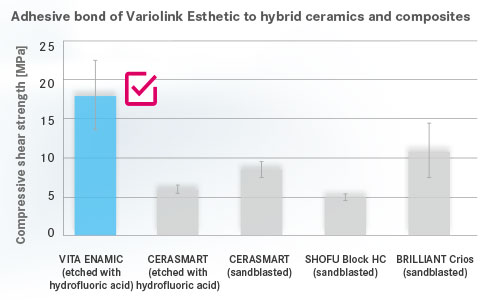

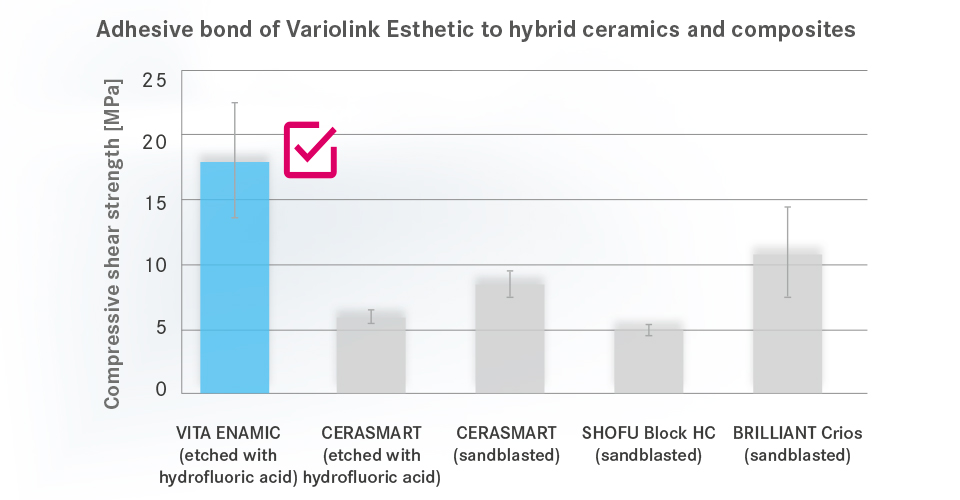

Dr. Berit Müller: In this series of tests, the adhesive bond of Variolink Esthetic to several CAD/CAM materials was investigated. For this purpose, five specimens, with two subsamples each, were produced from each material. When conditioning the samples, the respective manufacturer specifications were followed precisely. After bonding the subspecimens, the compressive shear strength was determined by means of a universal testing machine.

DV: In the adhesive bond of hybrid ceramics, you determined comparatively high adhesion values. What can these good values be attributed to?

Dr. Berit Müller: The good adhesive bond of the adhesion system to the hybrid ceramic VITA ENAMIC is due to the good preconditionability of the material by hydrofluoric acid etching. In addition, the comparatively high proportion of ceramic (86% by weight) also favors the adhesive bond.

DV: What is the difference between the adhesive bond to the hybrid ceramic in comparison to the composites tested?

Dr. Berit Müller: The hybrid ceramic has a polymer-infiltrated glass-ceramic matrix, which has a firmly sintered ceramic structure. The ceramic structure is roughened on the surface with hydrofluoric acid etching. The adhesion of the ceramic network remains completely intact. The result is that the roughened surface provides for good micromechanical retention. On the other hand, composites consist of a polymer matrix in which ceramic fillers are embedded. In the case of hydrofluoric acid etching, there is a risk that the fillers will dissolve out of the polymer matrix. The enlargement of the surface is achieved here using sandblasting.

DV: What influence does the preconditioning of the restoration have on the quality of the adhesive bond, and what are the differences between hybrid ceramic and composite?

Dr. Berit Müller: The preconditioning of the materials has a great influence on the adhesive bond. As described, the adhesive surface is roughened by the hydrofluoric acid etching, and this then ensures good dentition with the composite cement, which in turn has a positive effect on the adhesive bond as a whole. However, the conditioning method must not damage the material structure more deeply. In contrast to hydrofluoric acid etching, sandblasting poses a certain risk. The material roughening is less uniform, and the damage goes deeper into the material structure.

DV: You tested two conditioning protocols for the composite CERASMART. What did you discover in this process?

Dr. Berit Müller: GC is the only manufacturer to release two preconditioning processes for CERASMART: hydrofluoric acid etching and sandblasting. Therefore, both procedures were also tested. However, the preconditioning of CERASMART using hydrofluoric acid yielded inferior results in the test compared with preconditioning by sandblasting.

DV: From a scientific point of view, what are the key success factors for adhesive attachment in everyday practice?

Dr. Berit Müller: In addition to hydrofluoric acid etching, it is primarily the chemical bond between the material surface and the adhesive material that is important. This is what the bonding agent is for. If hydrofluoric acid etching or silanization is omitted, the adhesive values are significantly worse, and the probability of debonding increases.

Report 07/18