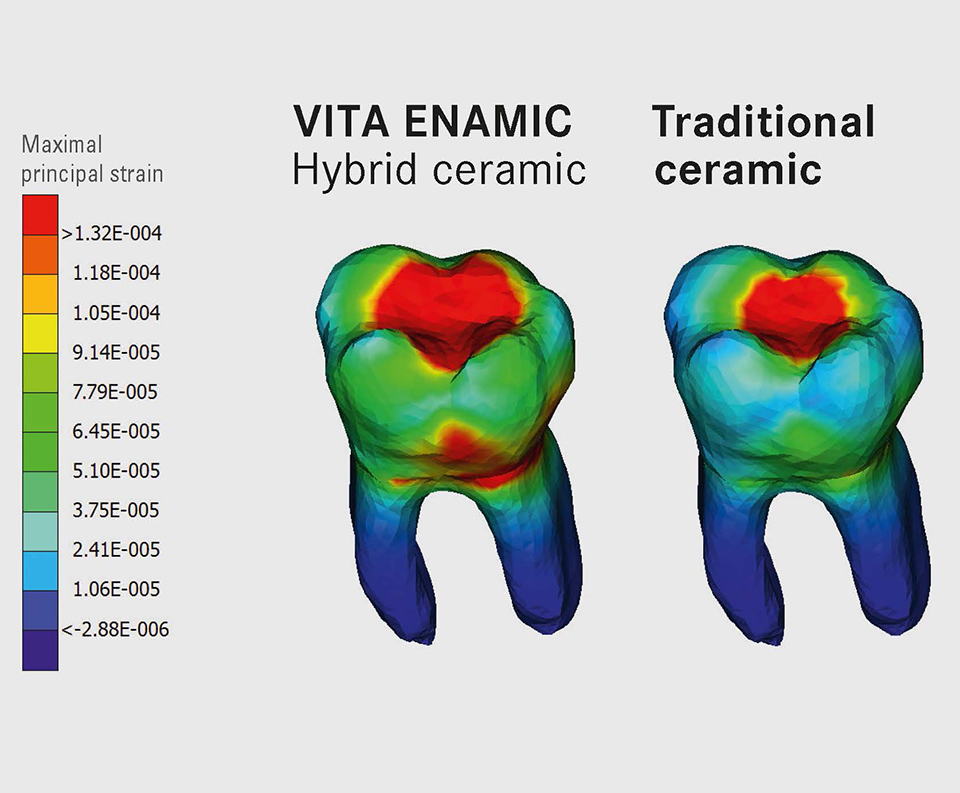

FEM simulation with hybrid ceramics provides new discoveries in biomechanics

The Fraunhofer Institute for Manufacturing Engineering and Automation (IPA) investigated the macroscopic deformation behavior of the hybrid ceramic VITA ENAMIC using FEM (Finite Elements Method). In the virtual load test, different load situations were simulated in order to then investigate occurring stresses and strains with restorations made of VITA ENAMIC and those made of traditional ceramics. Prof. Oliver Röhrle, PhD (University of Stuttgart, Institute for Mechanics, Stuttgart, Germany and Fraunhofer IPA, Stuttgart, Germany) reports on the simulation results in the following interview.

DV: Stress peaks occurring under a load can lead to the formation of cracks and damage in dental materials. What findings can an FE simulation provide in this case?

Prof. Oliver Röhrle: By analyzing stress peaks, weak points in the construction can be identified and provocation of a structural failure can determine the maximum load. This data is useful for designing materials and geometry that distribute stresses more efficiently under normal load conditions.

DV: How does the ceramic-polymer matrix of VITA ENAMIC behave under simulated load conditions, and how can the dual network structure minimize stress peaks?

Prof. Oliver Röhrle: The stress concentration, which otherwise leads to crack growth, is absorbed by the extensible polymer matrix.

DV: What is the mechanical behavior of the hybrid ceramic in the FE simulation of a loading situation, and how does this differ from traditional ceramics?

Prof. Oliver Röhrle: In general, it can be said that traditional ceramics do indeed feature a high pressure resistance, but are also very brittle. In contrast, VITA ENAMIC features high tensile properties thanks to the polymer portion.

DV: Do the results for VITA ENAMIC allow us to expect a low risk of crack formation since the materials show a relatively high degree of material stretching under stress?

Prof. Oliver Röhrle: For a more precise risk assessment, a non-linear numeric investigation would be required. But yes – plasticity prevents an abrupt structural failure.

DV: In your opinion, what are the distinctive features of the VITA ENAMIC dental material with regard to its mechanical properties?

Prof. Oliver Röhrle: Because the polymer partially absorbs the nascent energy associated with a crack and deforms accordingly, the progression of the crack under a constant load is hindered.

Report 03/16

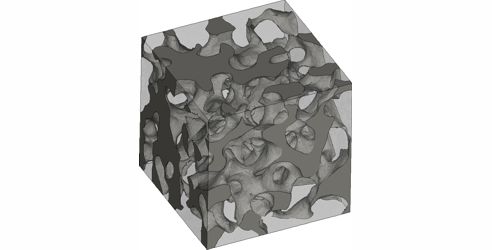

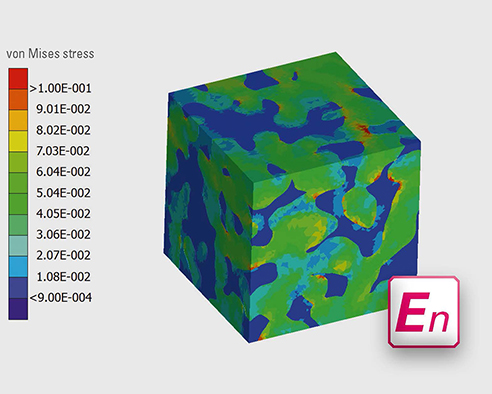

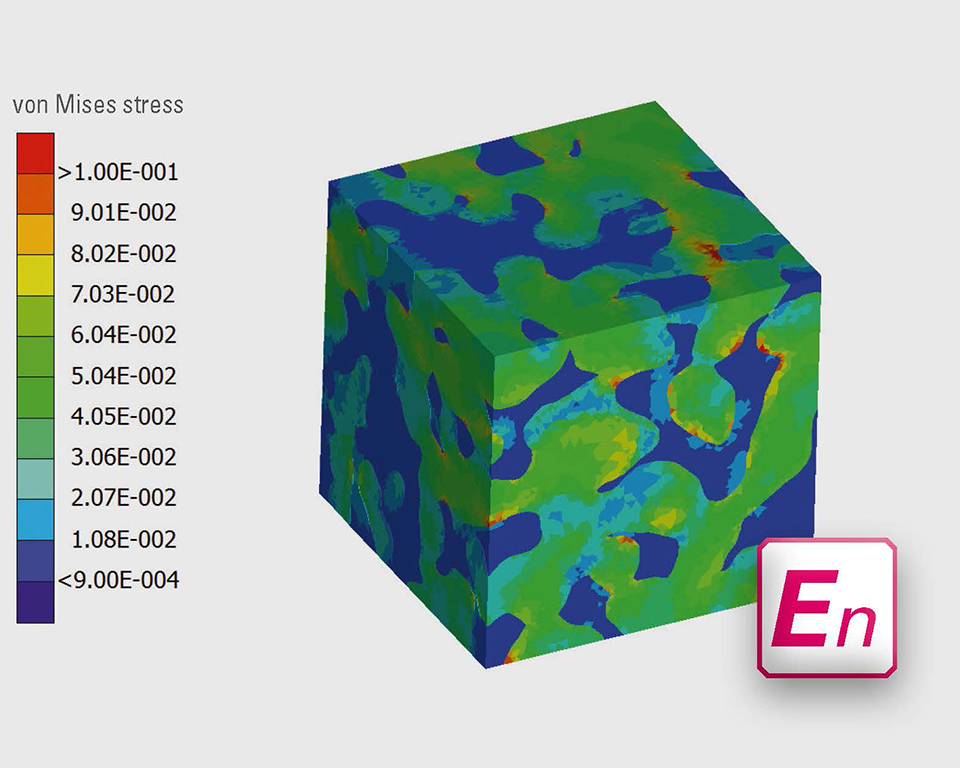

For this simulation, a complete tooth of hybrid ceramic and one of traditional ceramic were virtually manufactured. Then a typical load test is carried out on the tooth models, assuming idealized materials. Force is applied to a ball positioned on the tooth. Here, red represents the maximum principle strain, and the blue-colored area stands for slight or no deformation. The direct comparison shows that, in the VITA ENAMIC virtual test specimen, in contrast to the ceramic tooth model, nearly the whole crown is green to red, meaning that the hybrid ceramic yielded much more and thus absorbed the pressure.