Digital composite bridges of VITA YZ and VITA ENAMIC

Using VITA Rapid Layer Technology (RLT), a fully anatomical composite bridge consisting of a substructure and veneer structure is fabricated in a digital fabrication process. One advantage of this technology is that different materials and their specific properties can be combined with one another. For example, VITA YZ zirconia can be used for a stable substructure, and the relatively elastic hybrid ceramic VITA ENAMIC (VITA Zahnfabrik, Bad Säckingen, Germany) can be used for the veneering structure. In the following report, Hans Jürgen Lange, Master Dental Technician (Dental-labor Teuber, Darmstadt, Germany), explains the restoration steps with a comprehensive implant-supported reconstruction in the lower jaw using individual crowns and a composite bridge.

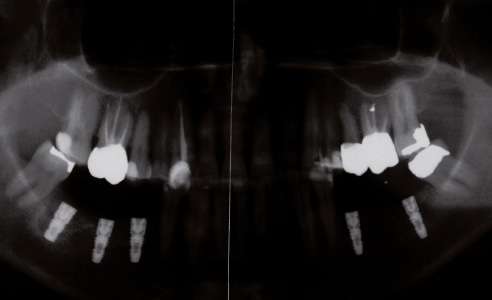

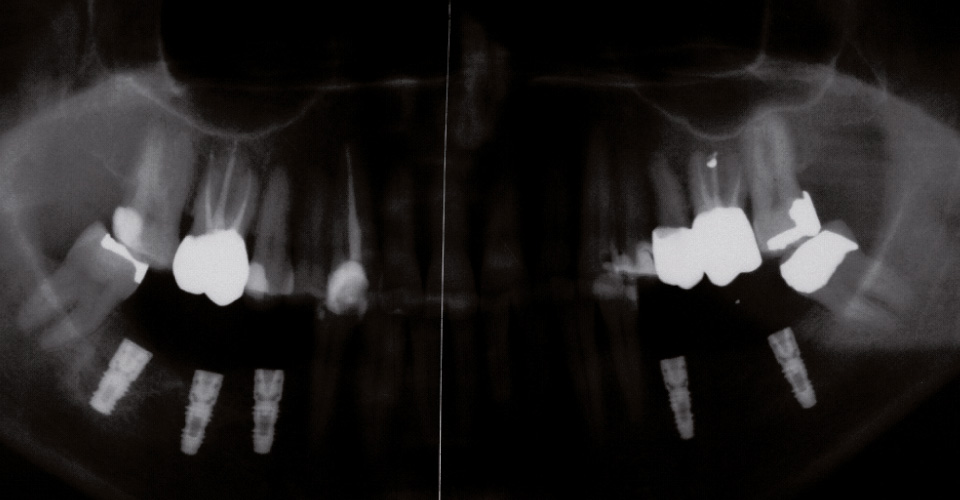

1. Initial situation

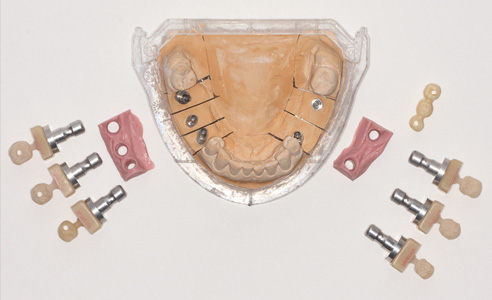

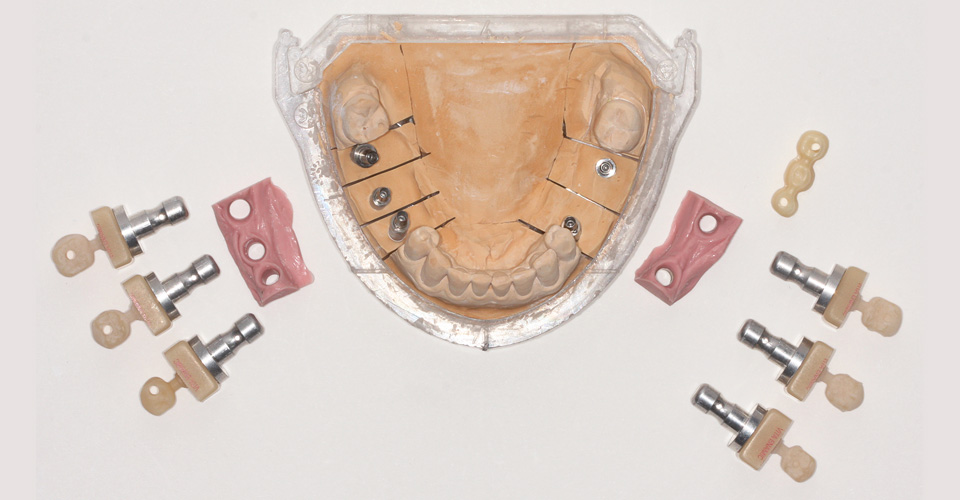

The patient was scheduled to be provided with a bridge on implants in regions 35 and 37, as well as with individual crowns on implants in regions 45, 46, and 47. Thanks to the shock-absorbing properties of VITA ENAMIC's integrated elasticity and high wearing comfort, it was decided to manufacture the superconstructions from hybrid ceramics. VITA ENAMIC IS blanks have an integrated interface including screw channel with an adhesive/titanium base. As a result, implant-supported restorations with the inLab MC XL system (Sirona Dental, Bensheim, Germany) can be created very simply. Since the hybrid ceramic is only approved for single tooth restorations, it was only possible to produce a bridge restoration using a digital composite solution.

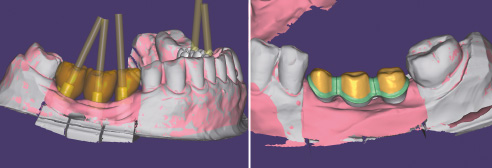

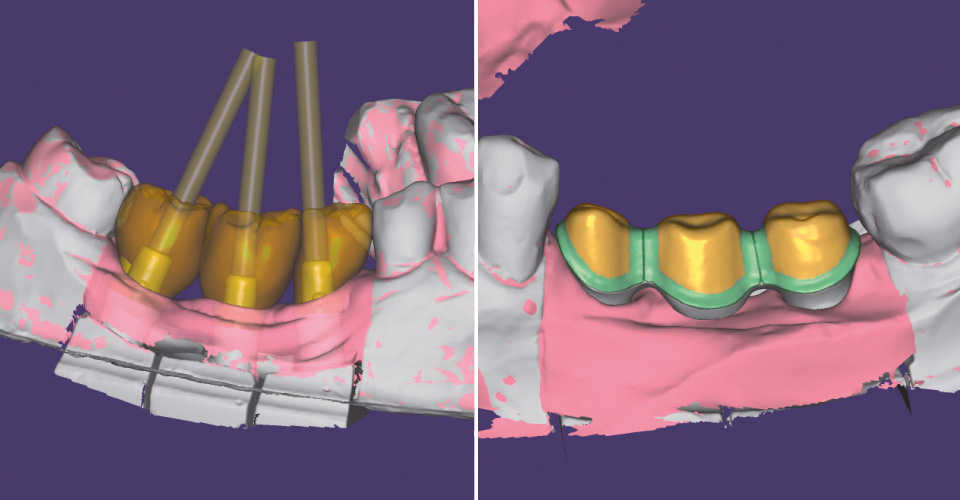

2. Fabrication of the substructure

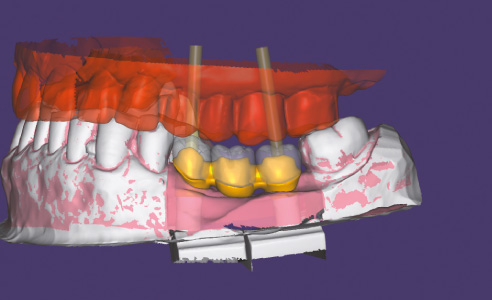

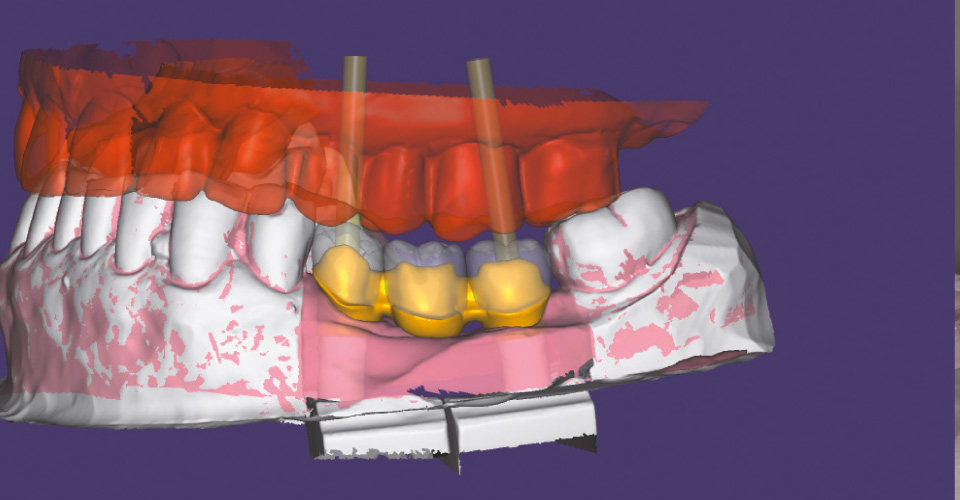

In the software exocad DentalCAD (exocad, Darmstadt, Germany), the titanium bases were initially designed fully anatomically, then were followed by a design that was reduced to almost a thimble framework (similar to the jacket crowns). The orientation of the screw channels, the space relations to the antagonists, etc., can be checked virtually at any time. After completion of the design for the substructure, this was milled from pre-stained VITA YZ zirconia, sintered, fitted, and provisionally fixed on the titanium bases.

3. Fabrication of the veneer structure

In contrast to the classical RLT method which requires only one scan, the framework was scanned again for an even more precise design of the veneer structure. In the case of the CAD, the positions of the screw channels were set according to the specified axis and later manually opened with the veneer structures from VITA ENAMIC. Emergence profiles and basal contact surfaces were made from zirconia to reach a high gloss polish that currently offers the greatest possible biocompatibility in contact with the gingiva. The bridge components are produced with the 5-axis simultaneous milling machine vhf S2 Impression (vhf camfacture, Ammerbuch, Germany).

4. Production of the composite bridge

The bonding followed the usual protocol for VITA ENAMIC, which has a good microretention after etching with 5% hydrofluoric acid. The zirconia is conditioned with a bonding agent. In addition, prior to the sintering process, we worked with a thin cutting disc in the horizontal plane for the restoration of micro-slits in the adhesive surfaces. The crowns were characterized with the stains of the VITA ENAMIC STAINS KIT, and the surfaces were sealed. In order to obtain the accentuations in the surface structure, the glazing should be as thin as possible.

5. Recommendation

For the reliable implementation of VITA RLT, the space relations must allow the minimum wall thicknesses for the restoration materials to be used. Implant situations are therefore very well suited. Thanks to the composite bridge solution, this patient was able to achieve a uniform, harmonious restoration result for the entire lower jaw.

Report 08/16