CAD/CAM implant prosthetic: Implant-supported crown restoration made of hybrid ceramics

The rigid anchoring of the implant body in the jaw bone means that implant-supported restorations lack the buffer function of the elastic fiber apparatus of natural teeth. Superstructures made of VITA ENAMIC can absorb masticatory forces due to their dentine-like elasticity, helping to take pressure off the implant and the antagonist teeth. VITA ENAMIC IS blanks (VITA Zahnfabrik, Bad Säckingen, Germany) have an integrated interface to adhesive/titanium bases. This allows one-piece, screwed abutment crowns without a cement gap, reducing the risk of peri-implantitis. In the following case report, Dr. Julián Conejo (Philadelphia, USA) describes restorations using abutment crowns step by step.

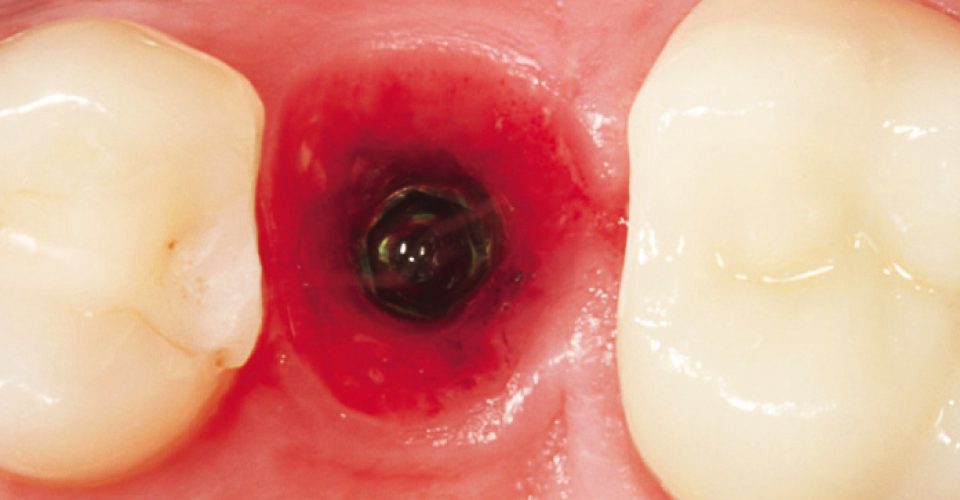

1. Diagnostics and immediate implantation

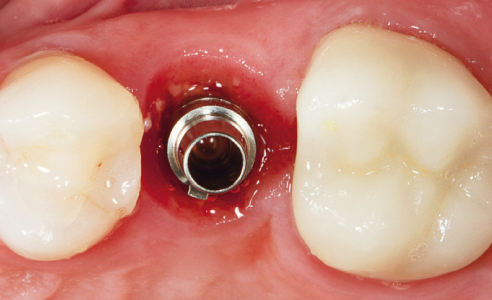

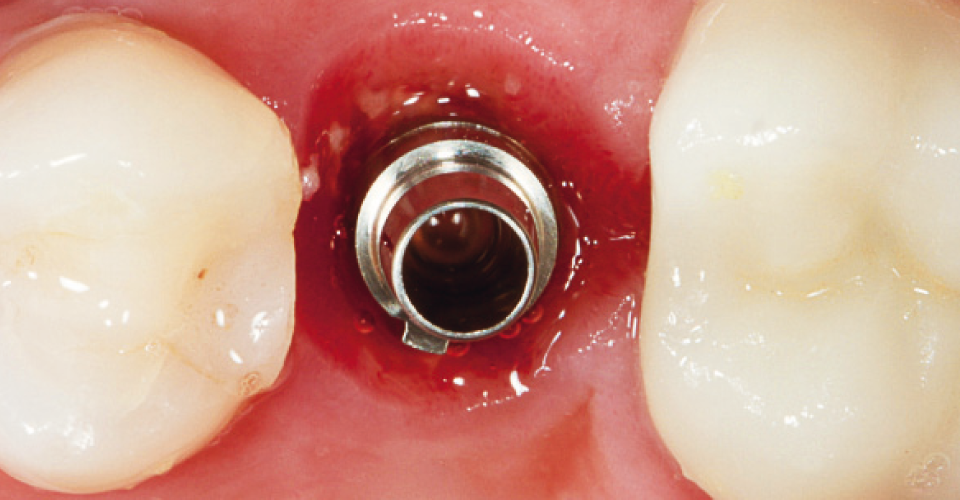

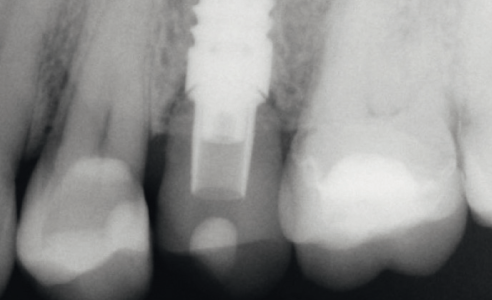

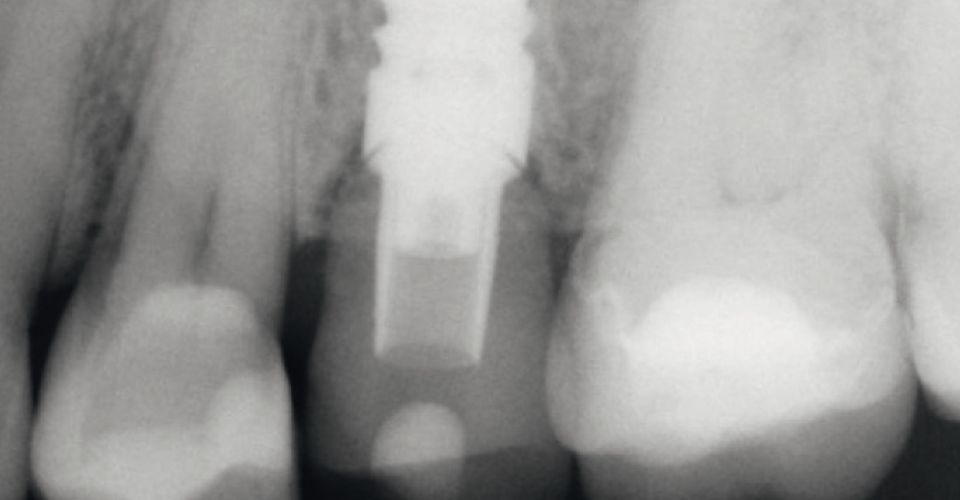

A 45-year-old patient complained of pain in region 25 when chewing. During the clinical examination of the endodontically treated tooth, a vertical root fracture was diagnosed. Clinical and radiological diagnostics showed no signs of inflammation. For that reason, an extraction method designed to protect the bone and an immediate implant were chosen. The tooth could be extracted with the greatest possible bone content. During the inspection of the extraction cavity, an entirely intact buccal bone lamella was found. After careful examination of the alveoli, the immediate implantation could be carried out. Since the primary stability was more than 35 N/cm², immediate loading with a screwed provisional temporary restoration without occlusal contact was possible in order to form the soft tissue during the healing process.

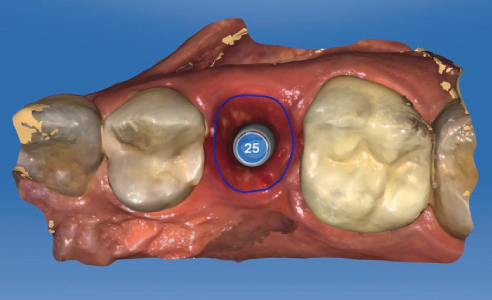

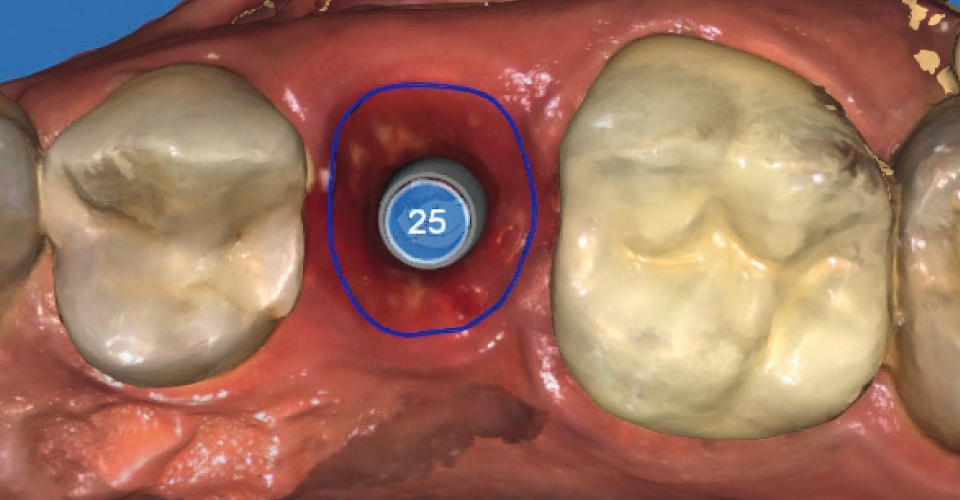

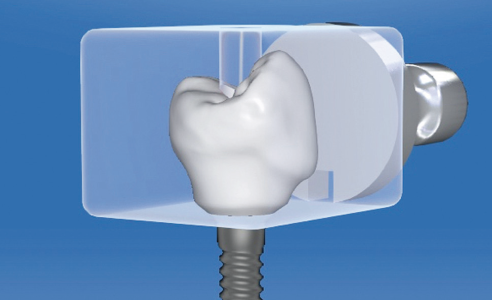

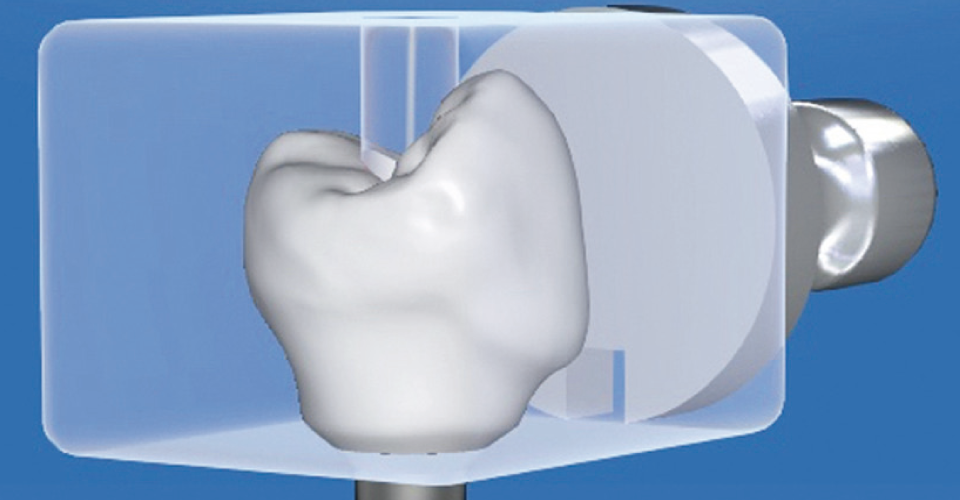

2. CAD/CAM fabrication

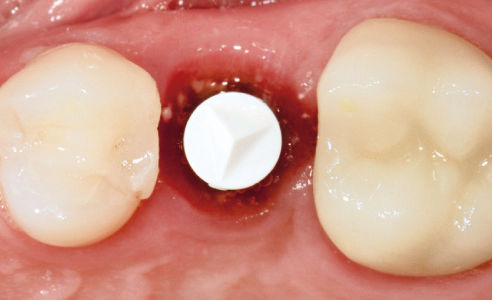

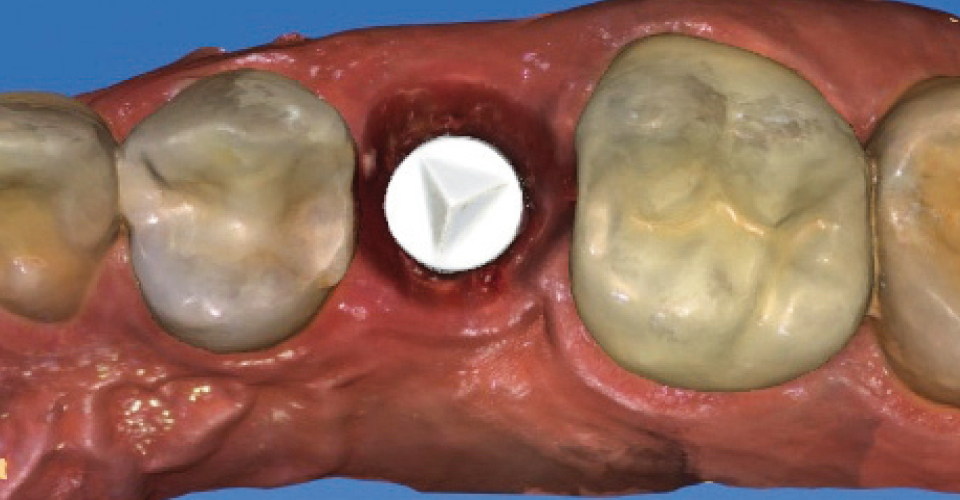

After three months of osseointegration, the soft tissue region at 25 showed a naturally formed emergence profile. Immediately after the temporary restoration was removed, the gingival development was recorded with the CEREC Omnicam (Sirona Dental, Bensheim, Germany). A scan post was then screwed onto the implant and a scan body was positioned on it. After a radiographic control of the fit, the three-dimensional implant position was scanned. A VITA ENAMIC IS blank was selected for the production of the final restoration. The morphology of the definitive abutment crown on the virtual model included a natural design with the CEREC software 4.4 so the soft tissue received optimal support. After the restoration was milled, manual polishing was performed with the VITA ENAMIC polishing set at a low speed. This resulted in a smooth surface in the transmucosal region.

3. Luting and integration

The adhesive base was sand blasted with aluminum oxide (50 micrometer, 3.0 bar), the interface and the screw channel of the VITA ENAMIC crown were etched with 5% hydrofluoric acid for 60 seconds. In order to form reliable adhesion with the dual-curing adhesive material PANAVIA V5 (Kuraray, Noritake), an MDP primer was applied to the relevant titanium and hybrid ceramic components before attachment. The finished restoration was then bolted at a torque of 35 N/cm². The screw head was covered with gutta-percha and the screw channel was sealed with direct composite material. The final radiographic control showed ideal bone conditions and a very good fit between the titanium base and the hybrid ceramic, thanks to the ready-made interface of the VITA ENAMIC IS blank. During the follow-up appointment after one year, the patient expressed that the hybrid ceramic abutment crown had a positive natural feeling.