Basics of digital prosthetic fabrication

The Ceramill Full Denture System (Amann Girrbach AG, Koblach, Austria) enables an efficient, precise CAD/CAM-supported denture fabrication. With VITA VIONIC SOLUTIONS (VITA Zahnfabrik, Bad Säckingen, Germany), there is now the right material system for every process step of digital production. Thanks to the combination of intelligent manufacturing technology and coordinated materials, laboratories can increase their productivity in prosthetics. With the Ceramill Mind software, VITA denture teeth can be used to create digital setups in more than 300 functional variants. Falko Noack, Engineer (Head of Application Technology R&D, Amann Girrbach AG, Koblach, Austria) answers questions about the digital workflow and its advantages.

DV: What must be considered in the digital workflow in order to achieve a good end result?

Falko Noack, engineer: Here, the same principles apply as in the manual process – if the working base does not fit, the final result will also show deficits. The most relevant step is not with the dental technician, but with the dentist. Digital total prosthetics require proper functional impressions to produce adequate models and an accurate bite registration.

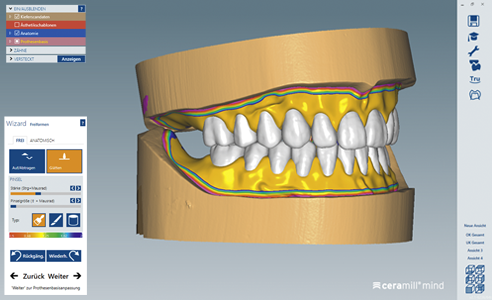

DV: What options are offered by the Ceramill Mind software for denture setup?

Falko Noack, engineer: In principle, with VITA denture teeth and the Ceramill Mind software, patient-specific denture settings can be created in more than 300 functional variants. In the front, the software allows individual positioning of each individual tooth. In the posterior region, the virtual alignment is done according to the specifications of digital model analysis. However, the modification of the digitally setup posterior teeth can only be done in conjunction with opposing quadrants, to ensure that ideal occlusion relationships are guaranteed at all times.

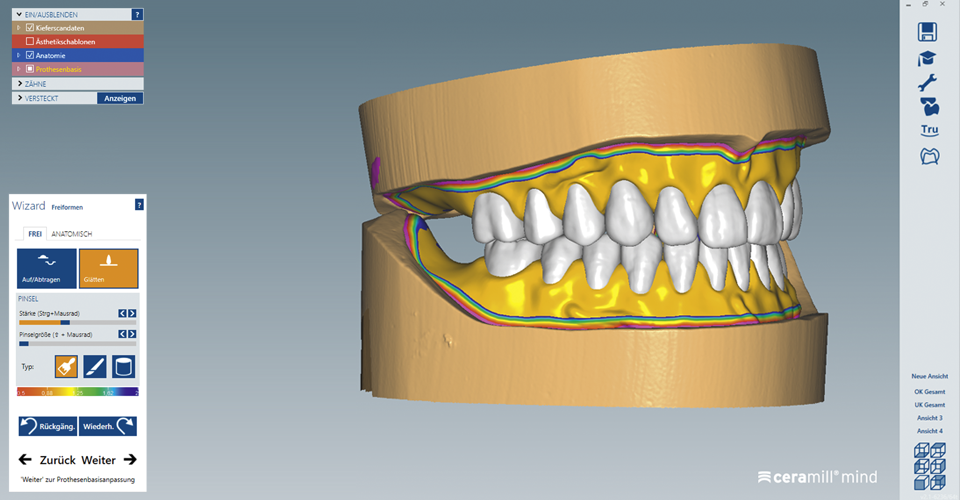

DV: What possibilities do technicians have for the setup and designing of the gingiva?

Falko Noack, engineer: For VITA VIONIC SOLUTIONS, laboratories have a choice between buccal and lingual concepts when designing with Ceramill Mind – depending on the anatomical situation and/or the desired philosophy. In addition, in terms of the occlusal position, the software supports the cross bite, as well as the normal bite. Ceramill Mind offers digital design tools, such as the free-form function of the wizard, for the individual design of the gingival portions.

DV: How is the try-in done with VITA VIONIC SOLUTIONS and Ceramill FDS?

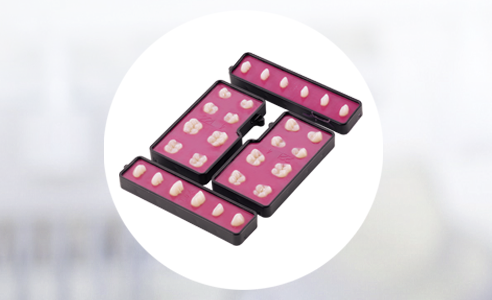

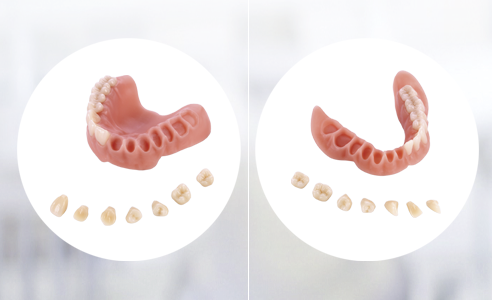

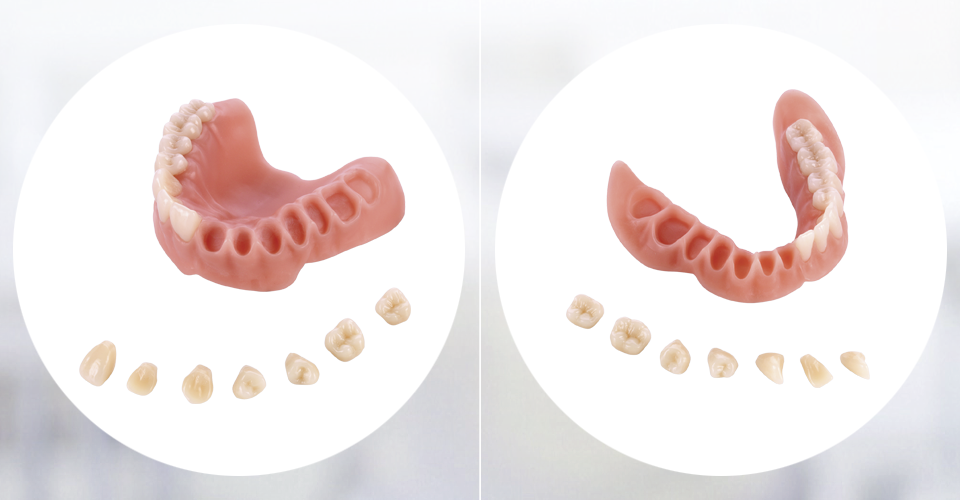

Falko Noack, engineer: For the clinical wax try-in, there are tooth and gingiva-colored VITA VIONIC WAX blanks. The laboratory can either mill a full-sized wax try-in from a tooth-colored blank, or produce the base from gingiva-colored blanks and affix the CAM-modified denture teeth in the milled alveoli. If the wax try-in was in full-size, then the CAM-modification takes place only on completion.

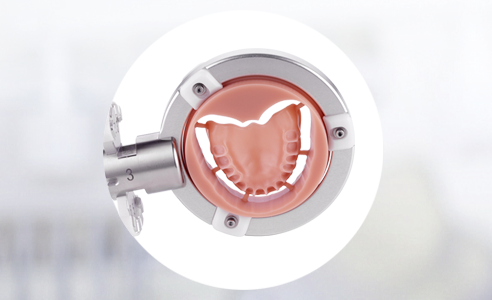

DV: How is the final completion done, and what components are needed?

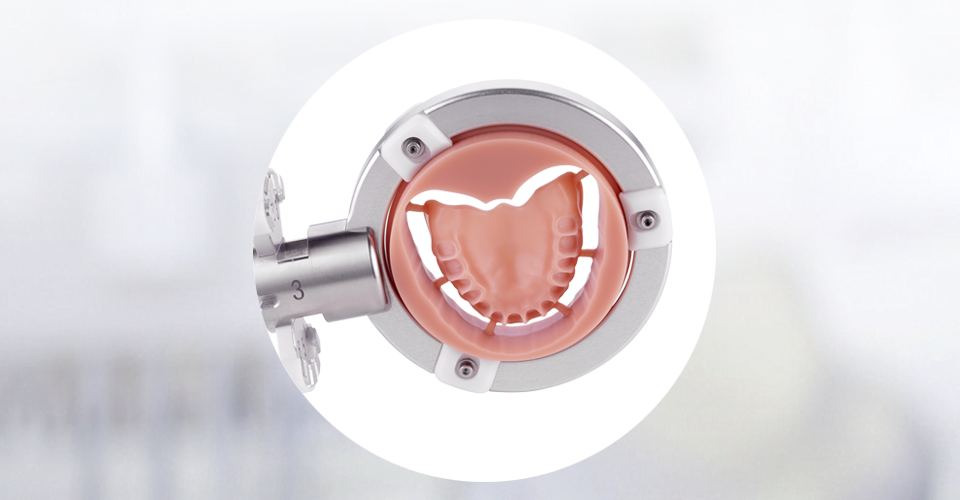

Falko Noack, engineer: After a successful try-in, the final denture base is milled using Ceramill Motion 2 from a PMMA blank. For this, the VITA VIONIC System offers VITA VIONIC BASE blanks in different gingiva shades. With the VITA VIONIC FRAME prosthetic frame solution, the CAM-supported basal and circular modification of the denture teeth can be “semi-automated,” according to the digital prosthetic design. This ensures a precise fit of the denture teeth to the milled alveoli. Adhesive fixation of the denture teeth in the alveoli of the base is then performed with the VITA VIONIC BOND fixation system.

DV: What are the advantages of digital prostheses with regard to precision and fabrication time?

Falko Noack, engineer: The factory system settings automatically provide correct occlusion and are very user-friendly. This results in increased precision and reduced time. In particular, the digital tooth setup allows a time savings of up to 60 percent compared to manual installation. By milling the wax or synthetic base, wax contraction or polymerization shrinkage are eliminated as sources of error.

Report 07/17