Abrasion resistance of materials: hybrid ceramic vs. composite?

The abrasion behavior of CAD/CAM materials is a building block of long-term clinical success. Dental materials should behave similarly to enamel, but at the same time be resistant to abrasion in order to guarantee function in the long term. If relatively "soft" materials are used, this can impair function due to increased material wear. Dipl.-Min. Berit Müller (Project Leader for VITA R&D, VITA Zahnfabrik, Bad Säckingen, Germany) reports on current measurement results from abrasion tests with hybrid ceramics and composite.

Elastic composites can absorb chewing forces, which reduces the risk of crack formation. But due to their low surface resistance in comparison to traditional ceramics, these materials wear down more quickly. With the VITA ENAMIC hybrid ceramic, a dental material has been developed that combines the positive characteristics of both ceramics and composites. But what is the abrasion behavior of this new material in comparison to traditional ceramic and composite materials?

Test setup and measurement results

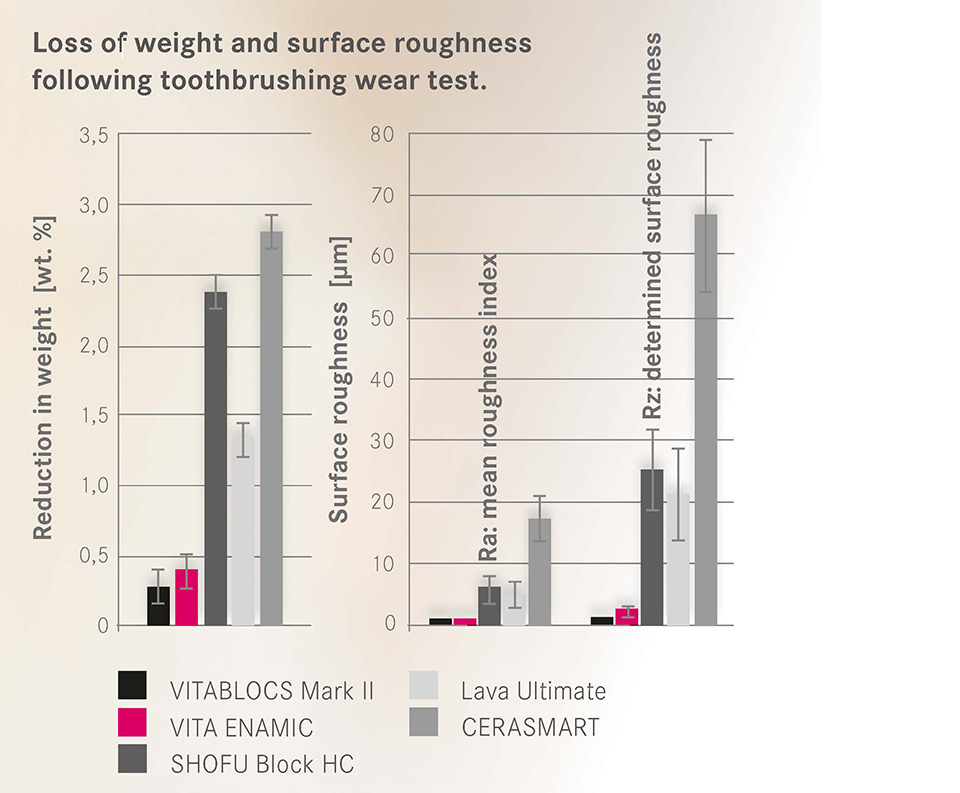

A comparison is only possible under defined laboratory conditions. For each material, five material samples were brushed with an abrasive toothpaste in a test system for 32 hours at a defined force. The weight and surface quality of the samples were determined before and after brushing. In this test, VITA ENAMIC was shown to be significantly more abrasion-resistant than the investigated composite materials. Furthermore, the determined results were very close to those of the feldspar ceramic VITABLOCS Mark II, which has been proven a million times over and which, due to its very enamel-like abrasion resistance, can be used as the gold standard1.

Prognosis and conclusion

A test run of 32 hours simulates use lasting several years. A commercially available, although abrasive toothpaste was used in the test. If patients used a less abrasive toothpaste, then less material wear can be expected for all investigated materials. The abrasion behavior for the hybrid ceramic VITA ENAMIC determined in the test is very similar to that of the proven VITABLOCS feldspar ceramics and allows us to expect sufficiently abrasion-resistant restorations. Due to its dual ceramic-polymer network structure, VITA ENAMIC is a unique dental material that combines many positive characteristics.

Report 03/16

References

1) Krejci, I. (1991). Wear of CEREC and other restorative materials. In Proceedings of the International Symposium on Computer Restorations: State of the Art of the Cerec Report 03/16; see note on p. 3 Method. Berlin: Quintessence Verlag, 245-251

Source Fig. 1

Internal investigation, VITA R&D, 03/2016, test report in the technical-scientific documentation of VITA ENAMIC; available at www.vita-zahnfabrik.com

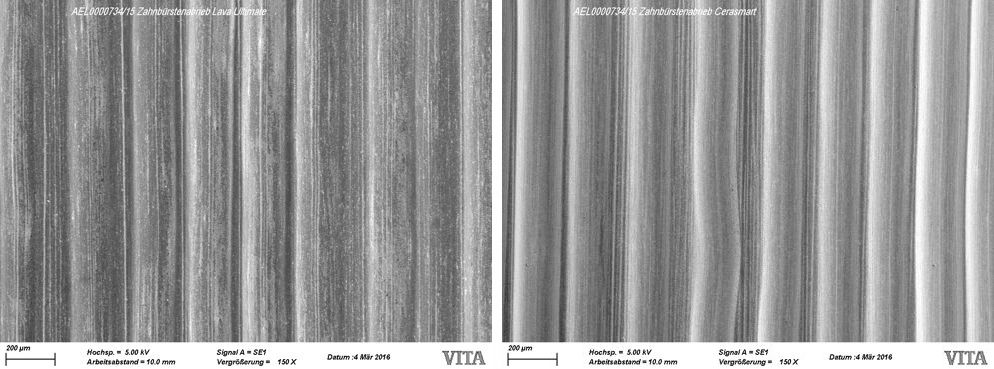

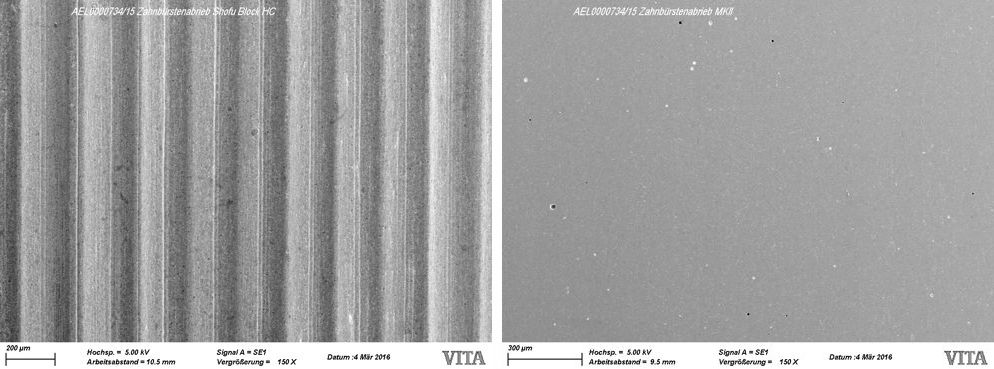

Source Fig. 2a-e

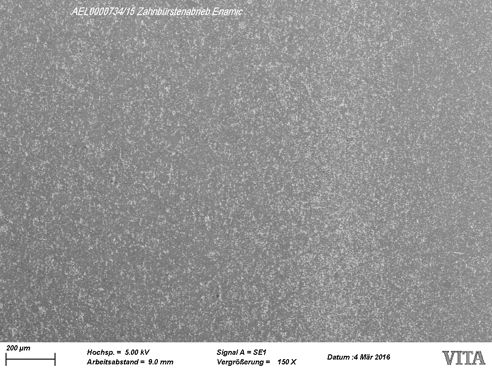

SEM images of material samples after toothbrush wear, VITA R&D, 150-fold magnification created with scanning electron microscope EVO MA 10 from Zeiss, 03/16