A metal-free overall solution: hybrid ceramics and zirconia implant

Full ceramic restoration concepts have become established in private practice. In implant-prosthetic reconstructions, titanium implants are frequently used, but ceramic implants are also growing in popularity. VITA Zahnfabrik (Bad Säckingen, Germany) has been offering a zirconia implant through ceramic.implant since 2014. Using a case report, Dr. Sigmar Schnutenhaus (Hilzingen, Germany) describes how a complete, metal-free implant-prosthetic restoration can be achieved using a superconstruction of VITA ENAMIC and ceramic. implant.

The demand for full ceramic therapeutic agents is also bringing about a rethinking of implant prosthetics. Implants made of zirconia have been offered for some time, and among other things, ensure excellent soft tissue management. "We have been working with ceramic.implant for several months now and have also discovered that the VITA ENAMIC hybrid ceramic is an ideal material for the superconstruction," reports Dr. Sigmar Schnutenhaus. By combining the ceramic implant with a hybrid ceramic crown, the common patient preference for an overall metal-free solution can be taken into consideration.

The implant from ceramic.implant is a onepart cylindrical implant with modified zirconia surface (cer.face®14). The VITA ENAMIC hybrid ceramic, as a material for manufacturing the superstructure, combines the advantages of a conventional ceramic with the positive properties of a composite. Thanks to the comparably elastic properties, chewing stresses can be absorbed to a certain extent. For the restoration of single tooth gaps in the posterior tooth region, we consider the therapy option presented here to be ideal.

1. Treatment planning

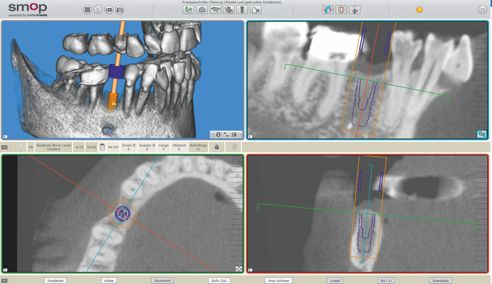

Since ceramic.implant is a one-piece implant, planning becomes extremely important. We favor virtual implant planning. The anatomical situation is evaluated using a DVT (Fig. 2). A wax-up modeled on the situation model serves as a template for the superstructure. The DICOM data from the DVT and the STL data from the wax-up are combined in the planning software and the implant position evaluated.

2. Insertion of the implant

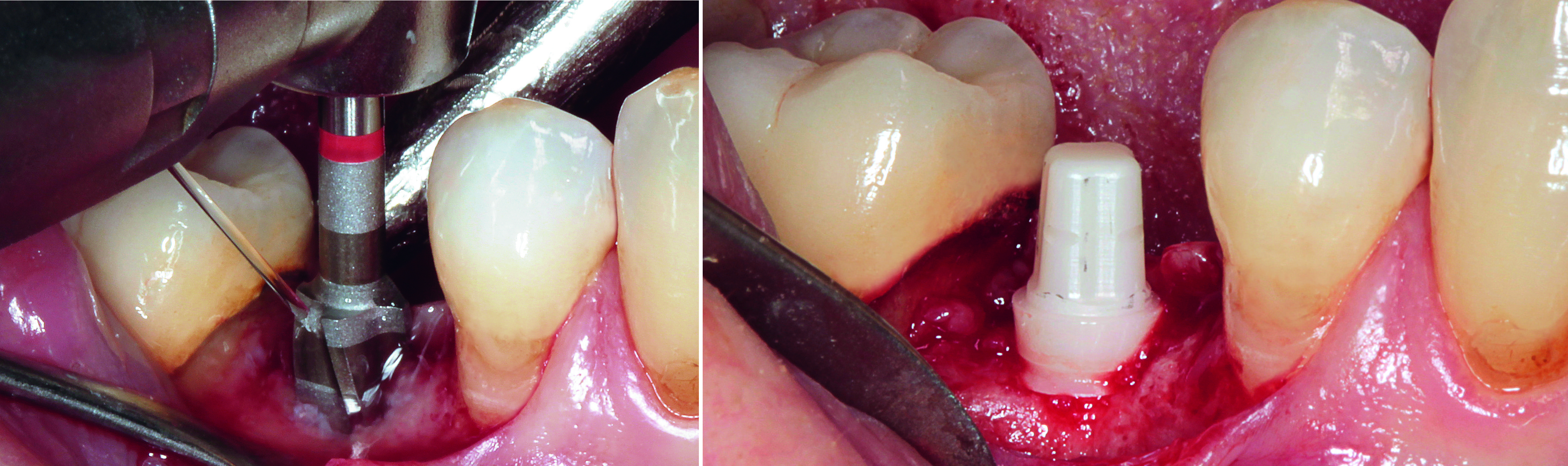

When the implant is inserted, either the template-guided or conventional process can be selected. After preparing the implant bed, the implant is inserted in the bone (Fig. 3 and 4), the surgical area is closed with two sutures, and the patient is discharged from the practice with a temporary restoration.

3. Manufacture of the superstructure

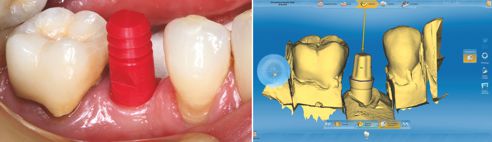

There is usually an ideal soft tissue situation after the necessary healing period. The adherence of the peri-implant gingiva around the zirconia implant is normally perfect. Special caps are available for the pick-up impression, which ensures a precise transfer of the situation from the mouth to the model (Fig. 5). After digitalization of the implant model, the crown is constructed using CAD software (Fig. 6). The CAM manufacturing of the superstructure then takes place using a VITA ENAMIC blank. Hybrid ceramic reconstructions can either be polished or characterized with light-curing stains after the grinding process. According to the manufacturer's instructions, the crowns should be cemented to the one-piece zirconia implant using a luting composite. The edge of the crown is ideally positioned in the visible area so that the danger of potential cement residues in the peri-implant area is eliminated.

4. Result and conclusion

Figures 7 to 9 show the situation before and after the prosthetic restoration with VITA ENAMIC. The implant crown is ideally integrated in shape, shade and function. If a metal-free implant prosthetic restoration is desired, the dentist can implement an overall functioning concept with the presented material combination. The simple surgical protocol during implantation and the efficient implementation of the superstructure must be highlighted. The ceramic.implant is a ceramic material alternative to titanium implants. The excellent soft tissue adaptation must be emphasized. In addition, the VITA ENAMIC hybrid ceramic is very well suited for the superstructure due to its material properties.

Report 03/16